An Industrial Professional’s Guide to Vinyl Siding: Composition, Lifespan, and Recycling

Vinyl siding is one of the most ubiquitous cladding materials in modern construction, particularly across North America and increasingly in parts of Europe. For homeowners, it represents a durable, low-maintenance, and cost-effective choice. For industrial professionals, manufacturers, and recycling operators, however, vinyl siding represents something more: a significant stream of high-quality polymer that, with the right processes, can be efficiently reclaimed.

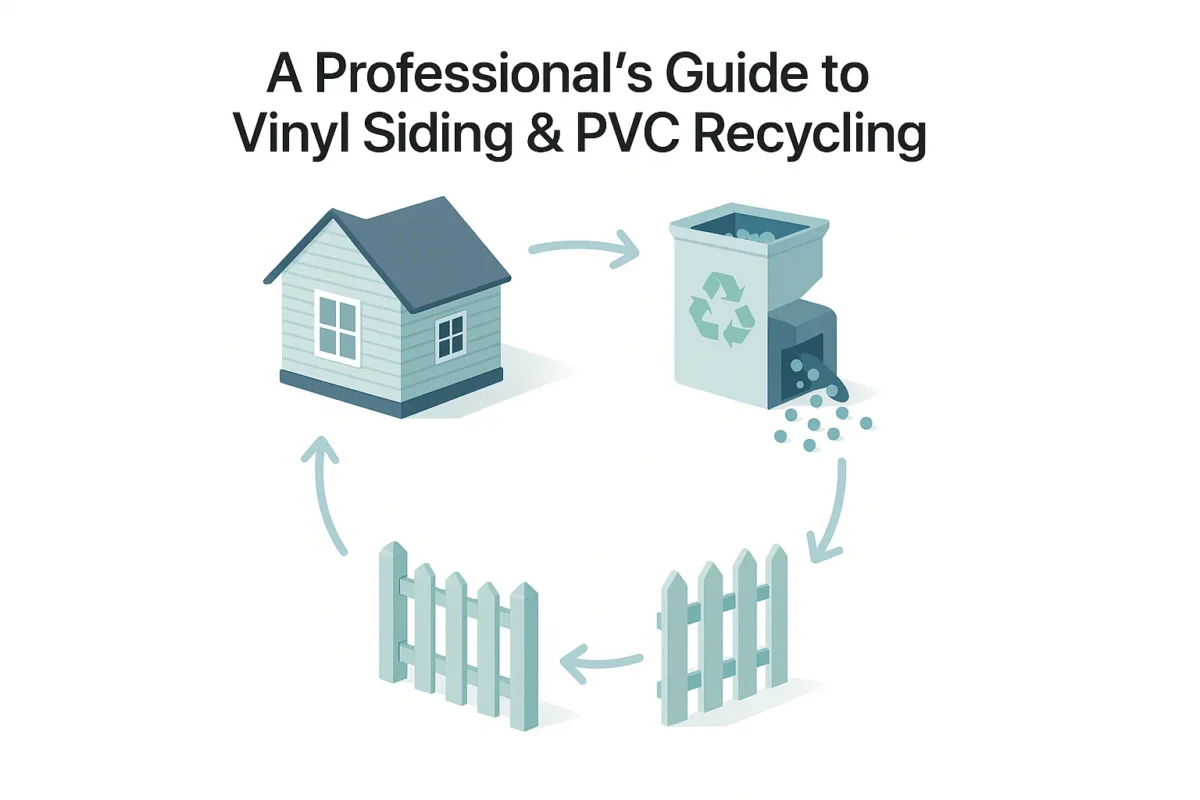

This guide provides a comprehensive overview of vinyl siding from an industrial perspective. We will delve into its material composition, manufacturing process, and most critically, the opportunities and methodologies for its end-of-life management through PVC recycling. Understanding this material is the first step towards unlocking its circular economy potential, a field where Rumtoo Machine specialises.

What is Vinyl Siding? A Look at the Material Science

At its core, vinyl siding is a plastic exterior cladding product engineered from Polyvinyl Chloride (PVC) resin. However, it is never just pure PVC. To achieve the durability, weather resistance, and colour retention required for decades of outdoor exposure, the PVC resin is compounded with a range of carefully selected additives.

The typical composition includes:

- PVC Resin (~80%): This forms the primary structure of the siding panel.

- Titanium Dioxide (~10%): A crucial additive that provides colour (typically brilliant white), opacity, and primary protection against UV degradation.

- Impact Modifiers: These compounds, often acrylic-based polymers, are integrated to improve the material’s resistance to cracking and breaking upon impact, especially in cold temperatures.

- Stabilisers: Heat and light stabilisers protect the PVC polymer chains from breaking down due to thermal stress during manufacturing and long-term exposure to sunlight.

- Pigments: For coloured siding, various pigments are added to the formulation to provide long-lasting, fade-resistant hues.

This specific formulation makes vinyl siding a rigid, resilient, and highly stable thermoplastic, perfectly suited for its application but also presenting unique considerations for its end-of-life processing.

The Path from Resin to Panel: The Manufacturing Process

Vinyl siding is predominantly manufactured through a process called co-extrusion. This advanced method creates a panel with two distinct layers of PVC, extruded simultaneously and fused together.

- The Substrate: This is the inner and thicker layer, comprising about 75% of the panel’s thickness. It is primarily made of PVC with impact modifiers, providing the siding’s structural integrity and strength.

- The Capstock: This is the thin, outer layer that is exposed to the elements. It contains a higher concentration of titanium dioxide and premium pigments for superior weather and UV resistance, ensuring colour fastness and long-term durability.

This two-layer structure is a cost-effective way to produce a high-performance product, concentrating the most resilient (and expensive) additives on the surface where they are needed most.

The End-of-Life Opportunity: The Case for PVC Recycling

For decades, used vinyl siding from demolition and renovation projects was destined for landfill. However, landfilling PVC is not only a waste of a valuable technical polymer but also raises environmental concerns.

The good news is that vinyl siding is highly recyclable. As a thermoplastic, it can be melted and reformed multiple times without significant degradation in quality, provided the recycling process is robust. Effective PVC recycling turns a waste product into a valuable feedstock for new manufacturing. This is where the quality of recycling equipment becomes paramount.

The industrial recycling process for post-consumer vinyl siding involves several key stages, each requiring specialised machinery to ensure the purity of the final output.

Diagram: A Generalised Vinyl Siding Recycling Workflow

A flowchart illustrating the recycling process:

[Box 1: Collection & Sorting] → [Box 2: Primary Shredding/Granulation] → [Box 3: Advanced Washing & Density Separation] → [Box 4: Mechanical Drying] → [Box 5: Pelletising/Compounding] → [Box 6: Manufacturing New PVC Products]

This process systematically removes contaminants like nails, screws, insulation foam, dirt, and adhesives, isolating the clean PVC. The washing and separation stage is particularly crucial for achieving the high purity required for many secondary applications. Advanced systems, such as the Rumtoo Machine recycling washing system, are specifically engineered to handle the complexities of construction and demolition waste, using friction washers, float-sink tanks, and high-speed dryers to produce a clean, high-value PVC flake.

Why High-Quality Recycling Machinery is Non-Negotiable

For recycling operators, the value of their output is directly proportional to its purity. Contaminated recycled PVC has limited applications and commands a lower price. Investing in high-performance recycling machinery from a reputable provider like Rumtoo Machine yields significant returns by:

- Maximising Purity: Effectively removing foreign materials to produce a near-virgin quality recycled PVC.

- Increasing Yield: Minimising the loss of good material during the separation process.

- Ensuring Consistency: Delivering a uniform flake or pellet size, which is critical for manufacturers using the recycled material.

- Improving Efficiency: Optimising water and energy consumption, reducing operational costs.

Frequently Asked Questions (FAQ)

1. Is all vinyl siding recyclable?

The vast majority of vinyl siding is technically recyclable. However, its recyclability in practice depends on the collection infrastructure and the capabilities of the recycling facility. Panels that are heavily painted (with non-PVC paint), or excessively contaminated with non-separable materials like silicone caulking can pose challenges.

2. What are the main challenges in recycling vinyl siding?

The primary challenge is contamination. Siding arrives from demolition sites mixed with wood, metal fasteners (nails and screws), insulation, and general construction debris. Separating the rigid PVC from these contaminants efficiently is the main goal of a well-designed recycling line.

3. What can recycled vinyl siding be used to manufacture?

High-quality recycled PVC from siding is a versatile material. It can be used to manufacture new building products like fencing, decking, window profiles, and electrical conduits. It is also used in flooring, automotive applications, and of course, as part of the substrate layer in new vinyl siding, closing the loop on its life cycle.

Unlock the Potential of PVC Waste Streams with Rumtoo Machine

Understanding vinyl siding is key to recognising its value beyond its initial use. As the industry moves towards a more sustainable, circular economy, efficient and effective PVC recycling is no longer an option, but a necessity.

At Rumtoo Machine, we provide robust, high-performance machinery that empowers businesses to transform PVC waste into a valuable resource. Our systems are designed for reliability, efficiency, and producing the highest quality output.

Ready to explore the opportunities in PVC recycling? Contact our team of experts today for a consultation or to request a quote on a system tailored to your specific needs.