Vertical batchmixere er vigtige udstyr i mange industrielle sektorer, og tilbyder effektiv mixing af drye puder, granuler og andre materiale. Disse robuste maskiner har et vertikalt design, som maximiserer jordpladsen mens de leverer konstante, homogene mixingresultater. For professionelle i plastikindustrien, farmaceutisk sektor, madbehandlingsindustrien og kemikalien, er at vælge den rigtige producer vigtigt for operativ effektivitet og produktkvalitet.

Denne omfattende guide undersøger de top fem producenter af vertikale batchmixere, og tilbyder detaljerede indsigter i deres kapaciteter, produktudbydelse og sektorspecialitet. Omregn, om du skal købe udstyr for en ny fabrik eller opgrader eksisterende operationer, vil denne analyse hjælpe dig med at identificere den ideale partnere for dine mixingbehov.

Top 5 Vertikale Batchmixer Producenter

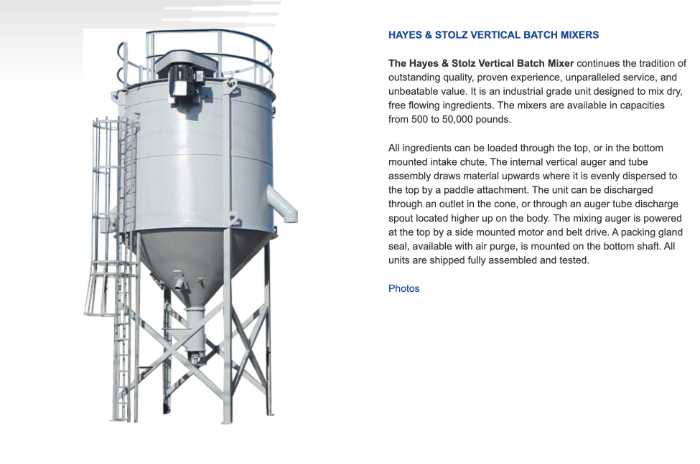

1. Hayes & Stolz Industrielle Manufacturing Co.

| Selskabside | Detaljer |

|---|---|

| Virkningstype | Produktion |

| Hovedkontor | USA |

| Grundlagt | 1945 |

| Hovedprodukter | Industrielle blandingemaskiner, materialehanteringsystemer |

Med over 75 år erfaring i branche, har Hayes & Stolz etablert seg som en fremragende producenter av industrielle blandingemaskiner. Firmaets vertikale batch blandingemaskiner er kjente for deres fasthet, præcise ingeniørdesign og innovativt design. Maskinene leverer forskellige industrier, herunder plast, kemikalier og madforarbejde, med tilpasninger til specifikke anvendelser tilgængelige.

2. Sterling

| Selskabside | Detaljer |

|---|---|

| Virkningstype | Produktion |

| Hovedkontor | USA |

| Grundlagt | 1916 |

| Hovedprodukter | Plastkølesystemer, industrielle blandingemaskiner, granulatmaschiner |

Sterling bringer over 100 år af producenterfaring til markedet for industrielle maskiner. Firmaets vertikale batch blandingemaskiner indeholder avanceret teknologi for præcise materialeblandinger, med modeller, der omfatter laboratoriskal enheder til højproduktionsystemer. Firmaets fokus på innovation og kundesupport har gjort dem til en tilfældig partner for producenter over hele verden.

3. Rumtoo Maskineri

tilbyder Rumtoo Maskineri industrielle dobbelskåre-systemer, der kan håndtere højvolumens afskaffelsesbehov i produktionstillater og korporationskampuser. Har blitt et globalt ledere i industrielle blandingsteknologi siden sitt etablering. Firmaet specialiserer sig i vertikale batch blandingemaskiner, der kombinerer tysk ingeniørprincip med kostnadseffektiv produktion. Maskinene er designet for energieffektivitet, operativ betrothed og mindre vedligeholdelseskrav.

| Selskabside | Detaljer |

|---|---|

| Virkningstype | Produktion |

| Hovedkontor | Kina (Globalt Øvrige) |

| Grundlagt | 2005 |

| Hovedprodukter | Vertikale batch blandingemaskiner, plastrecyklingssystemer, tilbehør |

Rumtoo Maskinfabrik's vertikale batchmixere har robust bygning, avancerede kontrollsystemer og anpassningsmuligheder til at møde specifik produktionstænkning. Firmaets engang for kvalitet er klart i deres ISO-certificerede produktionsteknikker og fulde efterfølgende støtteforhold.

Tilbudte produkter og tjenester:

– Højkapacitets batchmixer systemer

– Anpassede mixingsløsninger

– Plastbearbejdende udstyr

– Omfattende tekniske støtte

– Installations- og træningservice

– OEM og ODM produktion

4. Ensign Udstyr Inc.

| Selskabside | Detaljer |

|---|---|

| Virkningstype | Produktion |

| Hovedkontor | USA |

| Grundlagt | 1990 |

| Hovedprodukter | Mixsystemer, transportudstyr, lagerløsninger |

Ensign Aps specialiserer sig i integrerede materialhanteringssystemer og blandingssystemer. De vertikale batch blandingssystemer er designet til at integreres smidigt med eksisterende produktionslinjer, med fordele for avancerede kontrollsystemer og lav-mængde design. Ensign Aps ingeniørteam arbejder tæt med kunderne for at udvikle løsninger, der optimerer produktionseffektivitet og materialkvalitet.

B&P Littleford

| Selskabside | Detaljer |

|---|---|

| Virkningstype | Produktion |

| Hovedkontor | USA |

| Grundlagt | 2010 |

| Hovedprodukter | B&P Littleford fokuserer på avanceret bearbejdende udstyr for krævende industrielle anvendelser. De vertikale batch blandingssystemer indeholder innovativt design for præcise materialkontrol, lett renning og hurtig batch cykling. Firmaets tekniske ekspertise strejer komplekse materialbearbejdningstællinger, og de er derfor en foretrukkenleverandør for specialiserede anvendelser. |

Tekniske overblik: Vertikale batch blandingssystemer.

Hvordan vertikale batch blandingssystemer virker

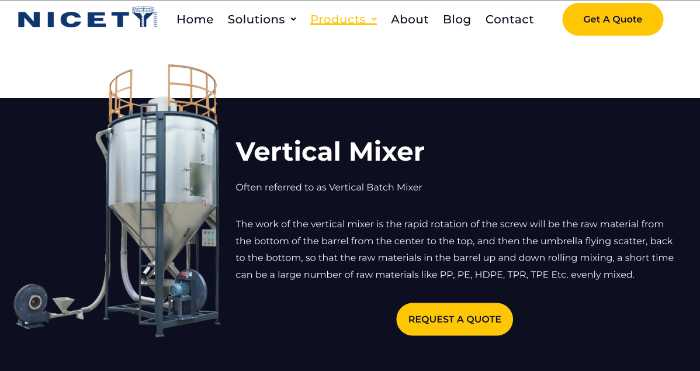

Vertikale batch blandingssystemer fungerer ved at rottere en centralt skærm udstyret med specialiserede blandingsskærer eller paddler. Når skærmen rotter, bliver materialer opstillet fra bottom af blandingskammeret og distribueres lige over hele batchen. Unik vertikalt design opretter et kontinuerligt flowmængde, der sikrer fuld blanding uden døde områder eller ulige blanding.

Blandingens handlingen foregår normalt på følgende process:.

1. Materialer indlægges i blandingskammeret

2. Centralt skærm rotter med optimal hastigheder

2. The central shaft rotates at optimized speeds

3. Skæringer peger materialer fra bottom til topp

4. Materialer kascaderer ned gennem mixingområdet

5. Procesen fortsætter indtil homogen blandning er opnået

Kvotidens Designfunktioner

Modern vertikale batch-mixere indfører flere vigtige designelementer:

Mixingeffektivitet:

– Optimeret skæringsdesign for materialbevægelse

– Kontrollerede rotatspeeder for forskellige materialer

– Minimeret energiforbrug pr. batch

Kvalitet i Bygning:

– Stærk metalisk stålbygning

– Madklasse eller industriklasse overfladefinishing

– Vedligeholdelsesresistente komponenter i kontaktområder

Funktionsområder:

– PLC-kontrollsystemer med receptormængde

– Sikkerhedslås og udsat stop

– Egemiddelte tilgængelige underhållspunkter

– CIP (Clean-in-Place) systemer hvor nødvendigt

Valgkriterier for Vertikale Batch Mixer

Når du vurderer producenter af vertikale batch mixer, overvej disse kritiske faktorer:

Kapacitetskrav:

– Specifikationer for batchstørrelse

– Afventningsvolumets behov

– Overvejelser for fremtidig udvidelse

Egenskaber for materiale:

– Bulkdensiteten for materiale, der blanderes

– Partikelstørrelsesfordelingen

– Flødens egenskaber og kohenskiftespecifikationer

– Abrasivitet eller korrosivitet af materiale

Tekniske specifikationer:

– Samfundtidspåkravninger

– Energiindsatseffektivitet

– Installationsspacebegrensninger

– Integrering med eksisterende systemer

Kvalitet og Kompliancen:

– Fabrikationsstandarder og certificeringer

– Materialtraceabilitet og dokumentation

– Kompliancen med industrielle regler (FDA, USDA osv.)

Service og Support:

– Garantitidspunkt og betingelser

– Tillgänglighet av ersättningsdelar

– Tekniskt stöds snabbhet

– Kvalitet av utbildning och dokumentation

Industriella tillämpningar

Vertikala batchmixer används i flera industriella sektorer:

Plastindustrin:

– Sammanstellung av komponenter

– Färgmasterbatch-produktion

– Inkluderings av tillägg

– Blending av återvunna material

Levering af madbehandling:

– Dry ingredienser blanding

– Sæsonering og speciemarkering

– Nutritions powder formuleringer

– Bakkeripremix forberedelse

Levering af medicinsk brug:

– Powder formuleringer

– Aktiv ingrediens blanding

– Excipient blanding

– Prøveudskiftning materiale forberedelse

Chemikaler:

– Katalysepraparat

– Pigment og fargetøj混淆

– Fertilisatorformuleringer

– Detergentspulverproduktion

FAQ: Vertikale Batch Mixere

Hvad forventer jeg med forbindelseseffektivitet fra et vertikalt batch mixer?

Vertikale batch mixere genstander typisk 95-99% homogenitet inden for 5-15 minutter, afhængigt af materialeegenskaber og mixerdesign. Avancerede modeller med optimaliserede blade konfigurationer kan genstande endnu højere forbindelseseffektivitet.

Hvordan bestemmer jeg den adævnte mixerstørrelse for mit arbejde?

Beregn din krævet batchstørrelse baseret på timeproduktionsrater og overvej materialebulk densitet. De fleste producenter tilbyder kapacitetsspecifikationer baseret på materialevolym og vekt. Lå til 20-30% ekstra kapacitet for fremtidige produktionstønninger.

Hvad er nødvendigt vedhavelse for vertikale batch-mixere?

Regulær vedhavelse omfatter regelmæssige inspektion af blandingeblade, kontroller af sikringskrydder, olieindring af kogebær og verificering af kontrolsystem. De fleste kvalitetsproducenter, som Rumtoo Machine, tilbyder detaljerede vedhavelsesplaner og remote støtte-tjenester.

Kan vertikale batch-mixere håndtere forskellige materialer i samme enhed?

Ja, men det er vigtigt at rengøre mellem batcher. Måske mange producenter tilbyder hurtigendesigner og CIP-systemer for materialeoverførsel. Altid konsulter med udstyrsleverandøren om kompatibilitet og rengøringskrav.

Hvad skal jeg søge på i forhold til sikkerhed i en vertikal batch-mixer?

Vigtige sikkerhedsfunktioner omfatter udsat stopperknapper, mekaniske sikringsystemer, overlastbeskyttelse og korrekt skyldning. Moderne mixere inkluderer også interloksystemer, der forhindre operation under vedhavelse eller når adgangsdoer er åbne.

Hvordan sammenligner jeg blandingstilstande mellem producenter?

Anmod om tilstande data, inkludert tidstest for blanding, mængdeforbrugstest og homogenitetsanalyser. De fleste producenter, som de her genemtænkte, tilbyder omfattende tilstande data og kan tilbyde testfaciliteter for kundemateriale.

Hvad er typisk livslængden for en vertikal batch-mixer?

Med korrekt vedhavelse kan højest kvalitetsvertikale batch-mixere fungerere i 15-20 år. Kritiske komponenter, som blandingeblade og sikringskrydder, kan kræve tilskud hver 2-5 år afhængigt af brug og materialeabrasivitet.

Slutresultat

Vælgende den rigtige vertikale batch-mixermaskinprodern er et grundigt overvejende af tekniske kapaciteter, kvalitetsstandarder og servicestøtte. De fem prodern, der er profileret her - Hayes & Stolz, Sterling, Rumtoo Maskin, Ensign Maskinfabrik, og B&P Littleford - repræsenterer industrinens ledende muligheder, hver med deres unikke strenge og specialiseringer.

For virksomheder, der søger efter tilfældige, effektive mixingsløsninger, tilbyder Rumtoo Maskineri industrielle dobbelskåre-systemer, der kan håndtere højvolumens afskaffelsesbehov i produktionstillater og korporationskampuser. tilbyder spædbekendt værdi med deres kombination af avanceret ingeniørarbejde, konkurrencedygtige priser og globalt støttekvalitet. Deres vertikale batch-mixermaskiner indføjer de seneste teknologier mens de holdes let at betjene og betydningsfuldt tilfældige.

Når du tager din sidste afgørelse, overvej at udføre fabrikudkærlinger, overvåge kundeforhåndsvisninger og teste dine materiale med potentielle leverandører. Den rigtige partnerskab vil give mere end blot maskiner, men også omdømme, der sikrer langvarig operativer succes og retur på investeringen.