Navigating the market for PET recycling machinery requires a clear understanding of the available technologies and their specific applications. This guide provides industry professionals, potential buyers, and international traders with essential information to source the right equipment efficiently. We will explore various machine types, their capabilities, and practical tips for selecting the best machinery for your operational needs.

Understanding PET Recycling Machinery

What is PET?

Polyethylene terephthalate (PET) is a durable, lightweight plastic predominantly used in beverage bottles and food packaging. Its excellent barrier properties and recyclability make it a preferred material in sustainable packaging solutions. PET is a staple in the plastic recycling industry due to its stability and high demand in circular economy models.

The PET Recycling Process

The PET recycling process begins with the collection and sorting of waste materials, such as used bottles and industrial scraps. These materials are cleaned, shredded into flakes, and thoroughly washed to remove contaminants. The clean flakes are then dried and processed through extrusion and pelletizing systems to produce recycled PET (rPET) pellets, which serve as raw material for new products. This closed-loop process significantly reduces landfill waste and supports environmental sustainability.

Compatible Machinery in Recycling Lines

A complete PET recycling line integrates several machines, each performing a critical function:

- Crushers/Shredders: Reduce bulk PET waste into manageable flakes.

- Waschanlagen: Remove labels, adhesives, and contaminants from flakes.

- Extruder: Melt and reform PET into consistent strands or pellets.

- Pelletieranlagen: Cut extruded strands into uniform pellets for reuse.

Optimizing the synergy between these machines ensures high efficiency and output quality.

Key Machinery Types and Their Functions

Plastic Crusher and Shredder Line

Crushers and shredders are fundamental in size reduction, transforming whole bottles and containers into flakes. These systems enhance downstream processing efficiency by providing uniformly sized material ideal for washing and extrusion.

Waschanlage

The washing line is crucial for purifying PET flakes. It typically includes hot washers, friction washers, and rinse units that eliminate impurities. The cleanliness of flakes directly influences the quality of the final rPET product.

Pelletizing Line

Pelletizing systems convert clean PET flakes into reusable pellets. These lines often include extruders, die faces, cutters, and cooling systems to produce consistent, high-quality pellets suitable for manufacturing new products.

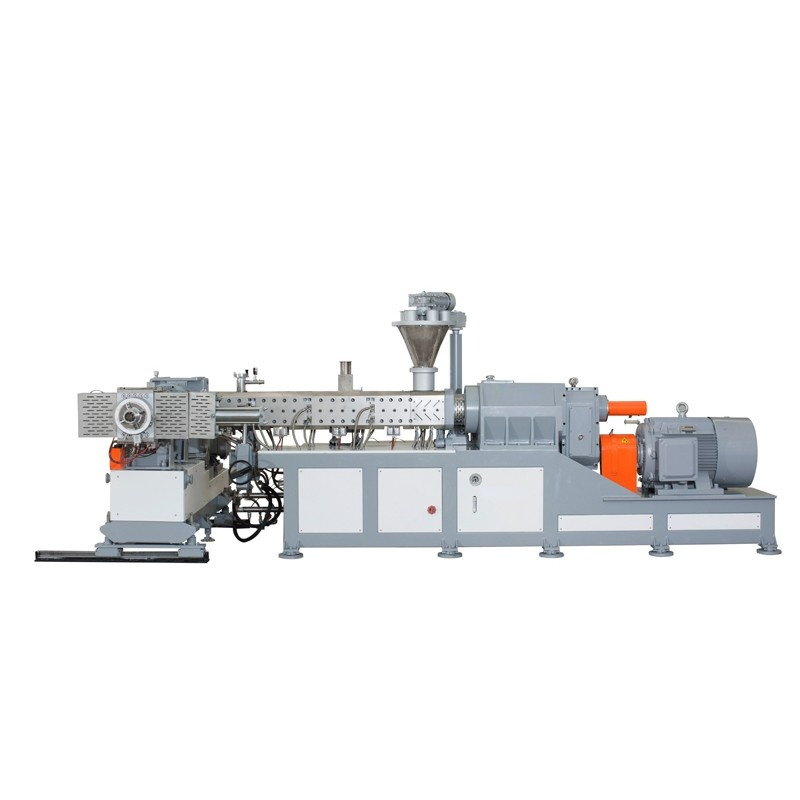

Extrusion Machine

Extruders melt PET flakes and form them into continuous strands. Advanced extruders feature precise temperature controls and screw designs to maintain material integrity and ensure output consistency.

Drying Systems

Drying is essential to remove moisture from washed flakes or pellets, preventing degradation during processing. Industrial dryers use desiccant beds or hot air to achieve the required moisture content efficiently.

Feeding and Melting Systems

Modern recycling lines incorporate automated feeding systems that ensure a consistent material flow. Combined with efficient heating and melting units, these systems optimize energy use and output quality.

Selecting the Right PET Recycling Machinery

When investing in PET recycling equipment, consider the following factors to align with your operational goals:

Machine Type and Functionality

Identify the specific processes your operation requires—whether shredding, washing, extruding, or pelletizing—and choose machinery that meets those needs precisely.

Capacity and Scalability

Evaluate the machine’s throughput capacity to ensure it matches your current and projected volume requirements. Scalable systems allow for future expansion without significant reinvestment.

Build Quality and Durability

Opt for robust construction and high-quality components to minimize downtime and maintenance costs. Stainless steel contact parts are preferable for corrosion resistance and longevity.

Energie-Effizienz

Select energy-efficient models to reduce operational costs and environmental impact. Look for features like variable frequency drives (VFDs) and heat recovery systems.

Supplier Reputation and Support

Partner with reputable manufacturers like Rumtoo-Maschine that offer comprehensive after-sales service, technical support, and readily available spare parts.

Tips for Sourcing the Best Machinery

Industry Recommendations

Seek advice from peers and industry associations to identify reliable equipment suppliers and proven technologies.

Online Research and Reviews

Utilize industry forums, review sites, and supplier websites to compare machine specifications, prices, and user feedback.

Evaluate Total Cost of Ownership

Consider not only the initial purchase price but also installation, operation, maintenance, and potential upgrade costs.

Request Demonstrations and Trials

Whenever possible, arrange for equipment demonstrations or trial runs to assess performance in real-world conditions.

Verify Compliance and Certifications

Ensure machinery meets relevant international standards and certifications for safety, quality, and environmental compliance.

FAQ-Abschnitt

Q: What is the typical output capacity of a PET washing line?

A: Capacities vary widely, from small-scale lines processing 500 kg/h to large systems handling over 3000 kg/h. Your choice should align with your feedstock availability and production targets.

Q: How often does PET recycling machinery require maintenance?

A: Regular maintenance schedules depend on usage intensity, but generally, critical components should be inspected weekly, with comprehensive servicing quarterly.

Q: Can PET recycling lines handle colored or contaminated materials?

A: Advanced washing and sorting systems can process colored and lightly contaminated PET, though heavily soiled materials may require pre-treatment.

Q: What is the average ROI period for PET recycling equipment?

A: Return on investment typically ranges from 18 to 36 months, depending on factors like material costs, energy prices, and end-market demand for rPET.

Q: Are turnkey solutions available for PET recycling plants?

A: Yes, suppliers like Rumtoo-Maschine offer customized turnkey solutions that include design, installation, commissioning, and training.

Branchentrends und Zukunftsaussichten

The global recycled plastics market is expanding rapidly, driven by regulatory pressures, corporate sustainability commitments, and consumer demand for eco-friendly products. Key trends include:

- Technologische Fortschritte: Automatisierung, AI-gestützte Sortierung und energieeffiziente Verarbeitung werden zum Standard.

- Kreislaufwirtschaftsinitiativen: Erhöhte Bedeutung der Schließung des Kreislaufs in der Plastikproduktion und -verbrauch.

- Regulatorische Unterstützung: Regierungen weltweit setzen Maßnahmen um, die den Einsatz von recyceltem Material in Verpackungen vorschreiben.

- Marktdiversifikation: rPET wird nicht nur in Verpackungen, sondern auch in Textilien, Automobilteilen und Baustoffen verwendet.

Investitionen in moderne PET-Recyclingmaschinen positionieren Unternehmen, um diese Trends zu nutzen und zur Umweltverträglichkeit beizutragen.

Schlussfolgerung

Die Auswahl der richtigen PET-Recyclingmaschinen ist eine strategische Entscheidung, die die Betriebseffizienz, die Produktqualität und die Einhaltung der Umweltauflagen beeinflusst. Durch das Verständnis der verschiedenen Maschinentypen, ihrer Funktionen und der wichtigsten Auswahlkriterien können Sie eine informierte Wahl treffen, die mit Ihren Geschäftszielen übereinstimmt. Für zuverlässige, leistungsstarke Recyclinglösungen entdecken Sie die Palette an Equipment von Rumtoo-Maschine, einem angesehenen Anbieter im Bereich der industriellen Maschinen.