Turning Waste into Worth: An Operational Guide to EPS Recycling for Businesses

Expanded Polystyrene (EPS), commonly known as foam, is ubiquitous in our modern world. From protecting fragile goods in transit to insulating buildings, its lightweight and versatile properties have made it an industrial staple. However, these same qualities present a significant environmental challenge, contributing to the “white pollution” that clogs landfills and harms ecosystems.

For manufacturers, logistics centres, and recycling enterprises across the USA and Europe, this challenge represents a profound opportunity. EPS waste is not merely rubbish; it is a valuable raw material waiting to be reclaimed. At Energycle Machine, we believe that with the right knowledge and technology, this bulky waste can be transformed into a significant revenue stream.

This guide will provide a clear, operational roadmap for establishing a successful EPS recycling line, detailing the commercial benefits, the core technical processes, and the critical role of high-performance equipment in achieving profitability.

The Compelling Business Case for EPS Recycling

Embracing EPS recycling is more than an environmental initiative; it is a strategic business decision that delivers tangible financial and reputational benefits.

1. Generate New and Lucrative Revenue Streams

Recycled EPS, processed into compressed blocks or high-density Polystyrene (PS) pellets, is a sought-after commodity in the global market. These materials are used to manufacture a wide range of products, including picture frames, decorative mouldings, construction materials, and stationery. By tapping into this circular economy, your business can convert a waste disposal cost into a consistent source of income.

2. Drastically Reduce Operational Costs

The high volume-to-weight ratio of EPS makes its disposal incredibly expensive. Landfill and transport fees are calculated based on volume, meaning bulky foam waste incurs disproportionately high costs. By compacting EPS waste, businesses can reduce its volume by up to 90%, leading to immediate and substantial savings on storage, handling, and disposal.

3. Enhance Your Corporate Brand and Social Responsibility (CSR)

In today’s market, sustainability is a key differentiator. Actively participating in EPS recycling demonstrates a commitment to environmental stewardship, enhancing your brand’s reputation among customers, investors, and regulatory bodies. This “green” credential can be a powerful asset, aligning your company with modern values and policies.

The Core Process of EPS Recycling: A Step-by-Step Breakdown

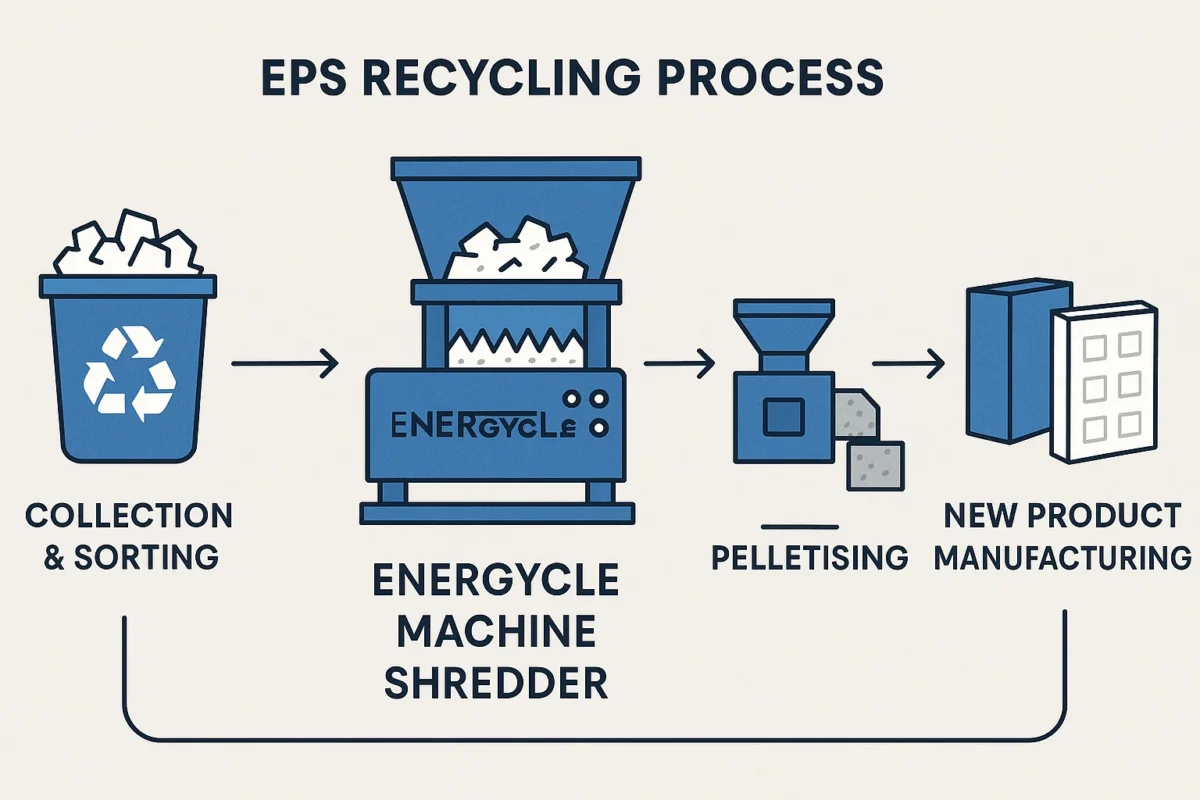

A successful EPS recycling operation is built on a logical and efficient workflow. Each stage is crucial for producing high-quality, marketable end-products.

Step 1: Collection and Sorting

The process begins with the collection of EPS waste from sources like industrial packaging, logistics hubs, or post-consumer goods. At this stage, it is vital to sort the material, removing contaminants such as tape, labels, food residue, and other plastics to ensure the purity of the final recycled product.

Step 2: Shredding – The Efficiency Engine

The Challenge: Raw EPS is bulky, lightweight, and surprisingly resilient. Feeding large, irregular pieces directly into a compactor is inefficient and can lead to blockages and equipment failure.

The Solution: The cornerstone of an effective recycling line is a professional-grade shredder. A powerful single-shaft or dual-shaft shredder, like those engineered by Energycle Machine, is designed to aggressively tear large EPS blocks into uniform, manageable pieces (typically 30-50mm). This pre-processing step is the source of efficiency for the entire system, ensuring a consistent flow of material to the next stage.

Step 3: Compaction and Densification

Once shredded, the EPS is ready for volume reduction. There are two primary technologies used in the industry:

- Cold Compaction: This method uses a powerful screw to physically compress the shredded foam, forcing the air out. It achieves an impressive compression ratio of up to 40:1, turning loose foam into dense, stackable blocks.

- Hot-Melt Densification: This technique uses heat to melt the EPS, which is then extruded into highly dense ingots. This process achieves the highest compression ratio, often reaching 90:1, resulting in a product that is cheaper to transport and easier to handle.

Crucially, the uniform material produced by an Energycle Machine shredder allows both compactors and densifiers to operate at peak efficiency and stability.

A professional flowchart illustrating the 5-step EPS recycling process:

(Collection & Sorting) → [Energycle Machine Shredder] → (Compaction / Densification) → (Pelletising) → (New Product Manufacturing)

Step 4: Pelletising

The dense blocks or ingots from the compaction stage are fed into a pelletiser. Here, the material is melted, extruded through a die into strands, cooled in a water bath, and then cut into small, uniform PS pellets. These pellets are the final, high-value product, ready to be sold to manufacturers.

Step 5: Application in New Products

The recycled PS pellets complete their journey by being used to create new, durable goods. This closes the loop, transforming single-use packaging into long-lasting products and contributing to a truly circular economy.

How to Select the Right EPS Recycling Equipment

Your choice of machinery will directly determine the profitability and reliability of your operation.

Why the Shredder is Your First and Most Critical Decision

An industrial shredder is the gatekeeper of your production line. A high-performance machine ensures high throughput and can handle tougher, denser EPS materials often found in appliance packaging. Investing in a robust shredder from Energycle Machine prevents bottlenecks and protects downstream equipment.

When selecting an EPS shredder, consider these key factors:

- Blade Design: Are the cutters optimised for the light, tough characteristics of EPS?

- Throughput Capacity: Does the machine’s output match your operational scale?

- Power and Durability: Is the motor and gearbox built for continuous, stable operation?

- Feed Opening: Can it accommodate the size of your typical EPS waste?

For businesses seeking maximum efficiency, Energycle Machine also offers integrated solutions. Our EPS recycling machine systems can combine shredding and pelletising into a single, automated line, reducing labour costs and factory footprint.

Preguntas frecuentes (FAQ)

1. Is EPS recycling genuinely profitable?

Absolutely. While initial equipment investment is required, the long-term returns are significant. The combination of revenue from selling PS pellets and savings from avoided landfill/transport fees creates a strong and sustainable business model.

2. What is the main difference between cold compaction and hot-melt densification?

Cold compaction uses physical force to compress foam into dense blocks, making it a lower-energy process. Hot-melt densification uses heat to melt the foam into even denser ingots, which often fetch a higher price due to lower transport costs per kilogram. The best choice depends on your operational scale, budget, and local market for recycled materials.

3. Why is a shredder necessary before a compactor or densifier?

A shredder breaks down large, awkward EPS pieces into a consistent, uniform size. This allows the compactor’s screw to grab and process the material efficiently without jamming. It dramatically increases the throughput, stability, and lifespan of the entire system.

Begin Your Profitable Recycling Journey Today

EPS recycling is a forward-thinking venture that aligns environmental responsibility with smart business acumen. The key to success lies in implementing a well-planned process powered by reliable, high-performance equipment. It all starts with a powerful and efficient shredding solution.

Is your facility struggling with mounting EPS waste? Are you ready to transform a costly problem into a profitable new enterprise?

Contact the experts at Energycle Machine today. Our team is ready to provide a complimentary consultation to help you design the perfect EPS recycling solution tailored to your specific needs. Request your free quote and take the first step towards a more sustainable and profitable future.