Vertical batch mixers are indispensable tools in various industrial sectors, adept at efficiently blending dry powders, granules, and other materials. These sturdy machines, characterized by their vertical layout, optimize floor space while ensuring uniform, consistent mixing outcomes. For professionals in the plastics, pharmaceuticals, food processing, and chemical industries, choosing the right manufacturer is pivotal for achieving operational efficiency and maintaining product quality.

This detailed guide scrutinizes the top five manufacturers of vertical batch mixers, offering in-depth analyses of their capabilities, product portfolios, and industry expertise. Whether you're acquiring equipment for a new facility or upgrading existing operations, this evaluation will assist you in pinpointing the perfect partner to meet your mixing needs.

Top 5 Vertical Batch Mixer Manufacturers

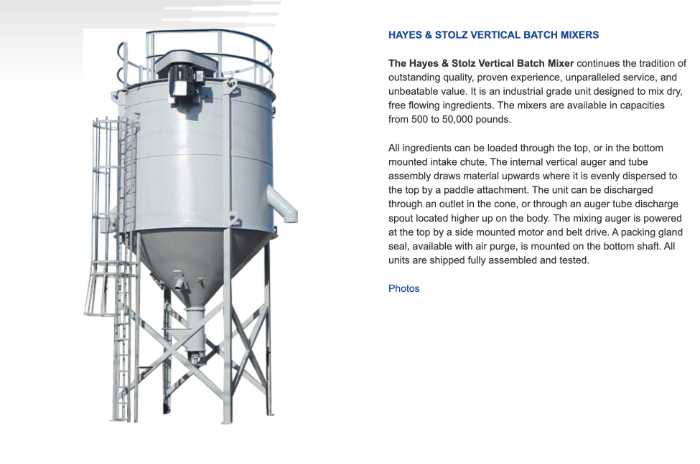

1. Hayes & Stolz Industrial Manufacturing Co.

| Company Overview | Features |

|---|---|

| Тип бизнеса | Manufacturing |

| Центрheadquarters | USA |

| Установлено | 1945 |

| - Over 75 years of industry experience | - Renowned for durable, precision-engineered, and innovative vertical batch mixers |

- Serves a wide range of industries including plastics, chemicals, and food processing.

- Offers custom solutions for specialized applications

| Company Overview | Features |

|---|---|

| Тип бизнеса | Manufacturing |

| Центрheadquarters | USA |

| Установлено | 1916 |

| - Over 75 years of industry experience | Sistemas de refrigeração de plástico, misturadores industriais, granuladores |

A Sterling traz mais de um século de experiência de fabricação para o mercado de máquinas industriais. Seus misturadores em lote vertical incorporam tecnologia avançada para a mistura precisa de materiais, com modelos que variam de unidades de laboratório a sistemas de produção de alta capacidade. A empresa se destaca pela inovação e pelo suporte ao cliente, tornando-se um parceiro confiável para fabricantes em todo o mundo.

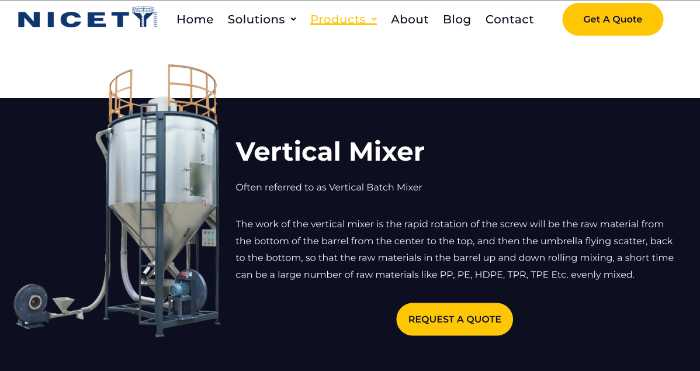

Rumtoo Máquinas

Rumtoo Machine Se tornou um líder global na tecnologia de mistura industrial desde sua fundação. A empresa se especializa em misturadores em lote verticais que combinam princípios de engenharia alemã com fabricação de custo efetivo. Seu equipamento é projetado para eficiência energética, confiabilidade operacional e manutenção mínima.

| Company Overview | Features |

|---|---|

| Тип бизнеса | Manufacturing |

| Центрheadquarters | Operações globais da China |

| Установлено | 2005 |

| - Over 75 years of industry experience | Misturadores em lote verticais, sistemas de reciclagem de plástico, equipamento auxiliar |

Os misturadores em lote verticais da Rumtoo possuem construção robusta, sistemas de controle avançados e opções personalizáveis para atender às necessidades de produção específicas. O compromisso da empresa com a qualidade é evidente nos seus processos de fabricação ISO-certificados e serviços de suporte pós-venda abrangentes.

Produtos e Serviços Oferecidos:

– Sistemas de misturadores em lote de alta capacidade

– Soluções de mistura personalizadas

– Устройства переработки пластика

– Полное техническое сопровождение

– Услуги установки и обучения

– Производство на OEM и ODM

4. Инк. Энсигн Эquipмент.

| Company Overview | Features |

|---|---|

| Тип бизнеса | Manufacturing |

| Центрheadquarters | USA |

| Установлено | 1990 |

| - Over 75 years of industry experience | Системы смешивания, конвейерное оборудование, решения по хранению |

Энсигн Эquipмент специализируется на интегрированных системах обработки материалов и смешивания. Их вертикальные батч-смешиватели разработаны для бесшовной интеграции с существующими линиями производства, с продвинутыми системами управления и низким уровнем обслуживания. Команда инженеров компании работает в тесном контакте с клиентами, чтобы разработать решения, которые оптимизируют производительность и качество материалов.

5. B&P Littleford

| Company Overview | Features |

|---|---|

| Тип бизнеса | Manufacturing |

| Центрheadquarters | USA |

| Установлено | 2010 |

| - Over 75 years of industry experience | Системы смешивания, оборудование для сушки, технология разделения |

B&P Littleford специализируется на передовом оборудовании для сложных промышленных применений. Их вертикальные батч-смешиватели включают инновационные функции для точного контроля материалов, простой очистки и быстрого цикла батча. Технический опыт компании распространяется на сложные задачи обработки материалов, делая их предпочтительным поставщиком для специализированных применений.

### Technical Overview: Vertical Batch Mixers

Vertical batch mixers function through a rotating central shaft that is fitted with specialized mixing blades or paddles. As the shaft rotates, materials are lifted from the bottom of the mixing chamber and are evenly distributed throughout the batch. The distinctive vertical design generates a continuous flow pattern that ensures comprehensive blending without the presence of dead zones or uneven mixing.

### How Vertical Batch Mixers Operate.

The operation of vertical batch mixers typically involves the following steps:

1. **Loading Materials**: Materials are introduced into the mixing chamber.

2. **Optimized Shaft Rotation**: The central shaft rotates at pre-set, optimized speeds.

3. **Lifting Materials**: Blades on the shaft lift materials from the bottom to the top of the chamber.

4. **Cascading Down**: Materials then cascade back down through the mixing zone.

5. **Achieving Homogeneous Blending**: The process continues until the materials are uniformly blended.

### Key Design Features

Современные вертикальные батч-миксеры включают несколько ключевых элементов дизайна:

Миксерная Эффективность:

- Оптимизированный дизайн лопаток для перемещения материала

- Управляемые скорости вращения для различных материалов

- Минимальное потребление энергии на партию

Качество Конструкции:

- Тяжелое стальное строительство

- Фасады пищевого или промышленного качества

- Устойчивые компоненты в контактных областях

Операционные Функции:

- PLC控制系统,具有配方管理功能

- -

- 安全互锁和紧急停止

- -

- 易于访问的维护点

- -

- 在必要时提供CIP(就地清洗)系统

- -

- 垂直批混选型标准

- -

Material Characteristics:

- Bulk density of the mixed materials

- Particle size distribution

- Flow properties and adhesion characteristics

- Abrasiveness or corrosiveness of the materials

Technical Specifications:

- Required mixing duration

- Power efficiency of operation

- Constraints on installation space

- Compatibility with existing systems

Quality and Compliance:

- Manufacturing standards and certifications

- Material traceability and documentation

- Compliance with industry regulations (FDA, USDA, etc.)

Service and Support:

- Warranty terms and conditions

- Availability of spare parts

- Technical support responsiveness

- Training and documentation quality

Industry Applications

Vertical batch mixers cater to a multitude of industrial domains:

**Plastics Industry:**

- Compound formulation

- Color masterbatch creation

- Additive integration

- Recycled material compounding

**Food Processing:**

- Dry ingredient amalgamation

- Seasoning and spice concoctions

- Nutritional powder synthesis

Bakery Premix Preparation

Pharmaceuticals:

Powder Formulations

Active Ingredient Blending

Excipient Mixing

Clinical Trial Material Preparation

Chemicals:

Catalyst Preparation

Pigment and Dye Mixing

Fertilizer Formulations

– Detergent powder production

FAQ: Vertical Batch Mixers

What mixing efficiency can I expect from a vertical batch mixer?

Vertical batch mixers are known for their high efficiency, typically achieving 95-99% homogeneity within a time frame of 5-15 minutes, which can vary based on the specific material properties and the design of the mixer. Advanced models, equipped with optimized blade configurations, can further enhance mixing efficiency.

How do I determine the appropriate mixer size for my operation?

To find the right mixer size, calculate your required batch size based on your hourly production rates and take into account the bulk density of your materials. Most manufacturers provide capacity specifications based on both material volume and weight. It's advisable to plan for an extra 20-30% capacity to accommodate future production growth.

What maintenance is required for vertical batch mixers?

Regular maintenance tasks include periodic inspections of mixing blades, seal checks, lubrication of bearings, and verification of the control system. Quality manufacturers, such as Rumtoo Machine, often provide detailed maintenance schedules and remote support services to ensure optimal performance.

Can vertical batch mixers handle different materials in the same unit?

Yes, they can handle various materials, but it's crucial to perform proper cleaning between batches to prevent contamination. Many manufacturers offer designs with quick-change features and CIP (Clean-In-Place) systems for efficient material changeover. Always consult with the equipment supplier to ensure compatibility and understand the necessary cleaning procedures.

What safety features should you consider when selecting a vertical batch mixer?

- Key safety features encompass emergency stop buttons, mechanical locking systems, overload protection, and adequate guarding. Modern mixers also feature interlock systems that halt operation when maintenance is underway or access doors are open.

How can you evaluate the mixing performance of different manufacturers?

- Request performance data such as mixing time tests, power consumption measurements, and homogeneity analysis reports. Reputable manufacturers, as listed here, typically provide comprehensive performance data and may offer test facilities for customer materials.

What is the expected lifespan of a vertical batch mixer?

- With proper maintenance, high-quality vertical batch mixers can last 15-20 years. Key components like blades and seals might need replacement every 2-5 years, depending on usage and material abrasiveness.

Recycled ABS filament embodies the synergy of performance, affordability, and environmental stewardship. It provides the resilience and adaptability needed for industrial-scale applications, while aligning with sustainable manufacturing objectives. As technology and material science advance, rABS emerges as a pragmatic, forward-thinking option for professionals committed to innovation and ecological responsibility. By incorporating recycled materials into your production process, you not only optimize operational efficiency but also make a significant contribution to a more environmentally conscious world.

When choosing the right vertical batch mixer manufacturer, what factors should you prioritize?.

- Carefully consider technical capabilities, quality standards, and service support. The five manufacturers highlighted here—Hayes & Stolz, Sterling, Rumtoo Machine, Ensign Equipment, and B&P Littleford—represent the industry's top options, each with unique strengths and specializations., Rumtoo Machine For businesses looking for dependable, efficient mixing solutions,.

- offers particularly strong value with a blend of advanced engineering, competitive pricing, and global support capabilities. Their vertical batch mixers integrate the latest technology while maintaining operational simplicity and reliability.