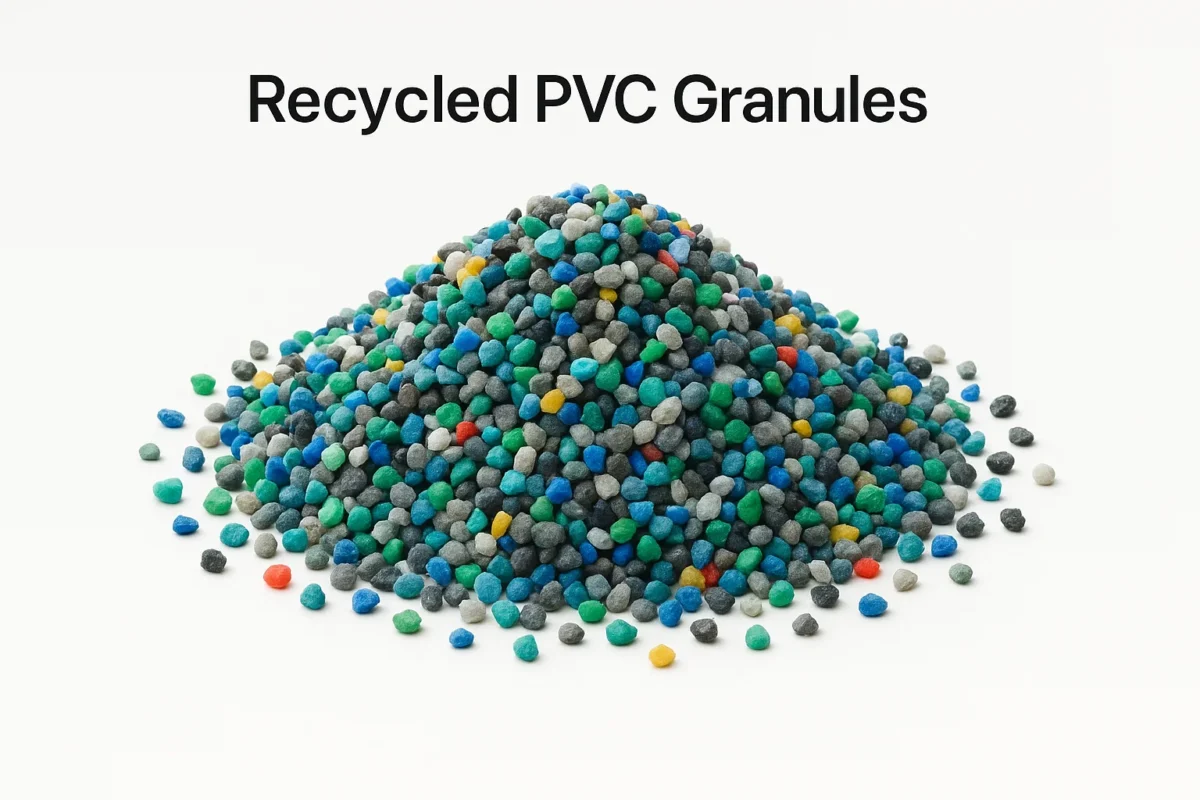

Polyvinyl Chloride (PVC) is a globally renowned, highly adaptable, and resilient plastic, indispensable for applications ranging from piping and flooring to window structures and cables. Despite its longevity, this characteristic poses an environmental concern. The answer lies in Recycled PVC (rPVC) pellets, a potent, environmentally conscious material that upholds the robust performance synonymous with PVC while actively promoting a circular economy.

By converting post-industrial and post-consumer PVC waste into premium raw materials, rPVC pellets provide manufacturers with a sustainable route to achieving their environmental goals without compromising on strength, chemical resistance, or long-term durability.

The Transformation Journey: From Waste to Resource

The recycling of PVC necessitates a meticulous, multi-step procedure to guarantee that the final pellets are both pure and high-performing. This process involves segregating various types of PVC and eliminating contaminants to produce a dependable manufacturing-grade material.

- Sourcing and Sorting: The process initiates with the collection of post-consumer and post-industrial PVC waste, encompassing remnants like old pipes, window profiles, vinyl siding, flooring, and cable sheathing. The first critical step is sorting the material into its two primary categories: rigid and flexible PVC.

- Shredding and Grinding: Following sorting, the segregated PVC is cleaned and subsequently fed into industrial shredders and grinders, which reduce the bulky items into small, uniform flakes.

- Purification and Separation: The flakes then undergo an advanced purification process. This may involve float-sink tanks, electrostatic separation, or other technologies to eliminate contaminants such as metal, wood, rubber, and other plastics.

- Melting and Pelletizing: The pristine PVC flakes are introduced into an extruder. They are melted under regulated temperatures, blended for uniformity, and then forced through a die. The resulting long, spaghetti-like strands are immediately cooled and chopped into small, consistent recycled PVC pellets.

- Quality Assurance: Every batch undergoes thorough quality checks, including color assessment, rigidity evaluation, chemical analysis, and melt flow index (MFI) testing, ensuring it complies with the specific requirements for its subsequent use.

Key Advantages: Selecting Recycled PVC:

Incorporating recycled PVC pellets into your manufacturing process offers substantial benefits that enhance your products, optimize your budget, and contribute positively to the environment.

- Exceptional Durability and Resistance: Recycled PVC maintains the distinctive characteristics of virgin PVC, boasting exceptional resistance to weathering, chemicals, and abrasion, making it ideal for applications requiring longevity.

- Significant Environmental Benefits: Utilizing recycled PVC significantly reduces the volume of plastic destined for landfills, conserves fossil fuels, and results in a notably lower carbon footprint compared to producing new PVC.

- Economical and Stable: Recycled PVC often presents a more cost-effective choice compared to virgin material, offering price stability and aiding in the efficient management of production costs.

- Fosters a Circular Economy: By generating demand for recycled materials, you actively contribute to the cycle of plastic waste and the establishment of a more sustainable industrial environment.

Naturally Versatile: Common Uses of rPVC

The strength and adaptability of recycled PVC make it a preferred material across various critical industries:

- Construction & Building: Utilized in pipes, conduits, window and door profiles, vinyl siding, fencing, and decking.

- Flooring: Employed in durable floor tiles, vinyl flooring, and mats.

- Automotive: Interior trim, floor mats, mud flaps, and wire insulation.

- Electrical: Sheathing and insulation for cables and wires.

- Consumer Goods: Garden hoses, footwear (like rain boots), and various molded products.

Preguntas Frecuentes (FAQ)

1. Are recycled PVC pellets as durable as virgin PVC?

Yes. When recycled using modern, controlled processes, rPVC pellets maintain the vast majority of their original mechanical properties. They exhibit excellent tensile strength, chemical resistance, and weatherability, making them a reliable and durable material for even demanding applications like construction pipes and window frames.

2. Can you recycle both rigid and flexible PVC?

Absolutely. Both rigid PVC (like pipes and profiles) and flexible PVC (like cables and flooring) are widely recycled. However, they must be sorted and processed separately because they have different formulations and properties. The resulting pellets are then used to create new rigid or flexible products, respectively.

3. Is recycled PVC safe for use in construction and consumer products?

Yes. The PVC recycling process involves stringent cleaning and purification stages to eliminate contaminants. The final rPVC pellets must comply with industry safety and performance standards, ensuring they are safe for their intended uses, ranging from building materials to consumer goods.

4. What are the main applications for recycled PVC?

The primary applications include the construction sector, where rPVC is utilized for pipes, flooring, and profiles. It is also extensively used for automotive components, electrical cables, and various industrial and consumer products requiring a robust, long-lasting material.

Ready to construct with strength and sustainability?

Select Recycled PVC Pellets for a high-performance material that aligns with your environmental objectives. Contact Us Today to find the appropriate grade for your project or to learn about the PVC recycling systems that enable this.