Introduction

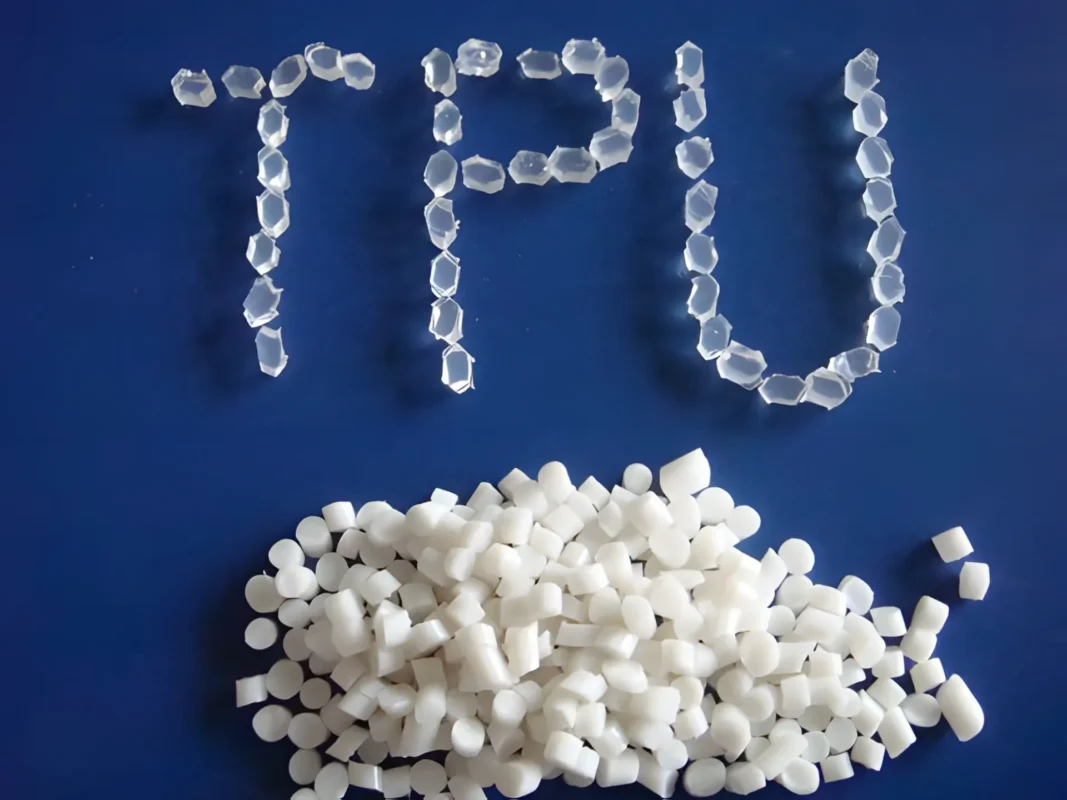

Thermoplastic Polyurethane (TPU) is a category of polyurethane plastics distinguished by their properties, such as elasticity, transparency, and resistance to oils, grease, and abrasion. These characteristics have led to its growing popularity across various industries, including automotive, footwear, and notably in the manufacturing of eco-friendly products like biodegradable gloves.

**Composition of TPU**

TPU is a block copolymer, featuring hard and soft segments that can be tailored to produce a broad spectrum of hardness, rigidity, and additional functionalities. The proportion and chemical structure of these segments dictate the polymer's flexibility and durability. This adaptability makes TPU uniquely suited for crafting items that must endure stress and wear while preserving their form and integrity.

**Key Properties and Benefits**

- **Elasticity**TPU exhibits the ability to stretch under physical strain and revert to its original form, making it an excellent choice for applications like elastic bands and protective cases.

- Долговечность**Resistance to Oils, Chemicals, and Abrasion**.

- Its resilience against oils, chemicals, and abrasion renders TPU a favored material for products subjected to harsh conditions, such as industrial components and medical devices.**Biodegradability**.

- **Transparency:**Certain TPU grades are engineered for biodegradability, decomposing under specific environmental circumstances, which aids in waste reduction and pollution control.

- Temperature ResistanceTPU excels in both low and high temperatures, making it indispensable for outdoor products or those subjected to fluctuating climate conditions.

Applications of TPU

TPU's adaptability enables its use in a wide range of applications:

- Partes de automóviles - Tubing, hoses, and seals that demand flexibility and resilience.

- - Medical devices, where non-toxic, sterilizable, and flexible materials are essential., - Footwear and apparel, capitalizing on its elasticity for comfort and longevity.

- - Electronics, benefiting from its robust properties in various components., leveraging its elasticity for comfort and durability.

- Electronics, 利用TPU在保护套和外壳中吸收冲击和提供保护。.

- 环保产品, ,特别是在生产可生物降解的消费品,如手套,这些产品在可持续市场中越来越受欢迎。.

: Recycled pellets are versatile, applicable in diverse sectors including packaging and automotive components.

TPU的生产相较于其他塑料可能更加环保,特别是在使用可再生资源制造时。其生物降解的潜力使其在产品废弃时减少环境足迹方面表现出色。然而,TPU的环境效益在很大程度上取决于其特定的化学配方和生产实践。.

Recycled ABS filament embodies the synergy of performance, affordability, and environmental stewardship. It provides the resilience and adaptability needed for industrial-scale applications, while aligning with sustainable manufacturing objectives. As technology and material science advance, rABS emerges as a pragmatic, forward-thinking option for professionals committed to innovation and ecological responsibility. By incorporating recycled materials into your production process, you not only optimize operational efficiency but also make a significant contribution to a more environmentally conscious world.

TPU因其不仅满足各种行业严苛的标准,而且与日益增长的生态和可持续性目标相契合而脱颖而出。其发展继续推进,有望在防护装备、医疗用品和消费电子等领域提供更广泛的应用解决方案。随着行业倾向于更可持续的实践,TPU有望处于前沿,提供结合性能与减少环境影响的解决方案。.

对TPU的这一探索揭示了它为何被视为通往更可持续和耐用未来的基石材料。其能够根据特定需求进行定制,同时保持环保特性,为材料科学的未来提供了一瞥,即功能性和环境责任并行不悖。.