The Sustainable and High-Performance Choice for Modern Manufacturing

In today’s competitive market, manufacturers face the dual challenge of delivering high-quality products while meeting growing demands for environmental responsibility. Recycled PVC granules rise to this challenge, offering a robust, eco-friendly, and cost-effective alternative to virgin materials without compromising on quality.

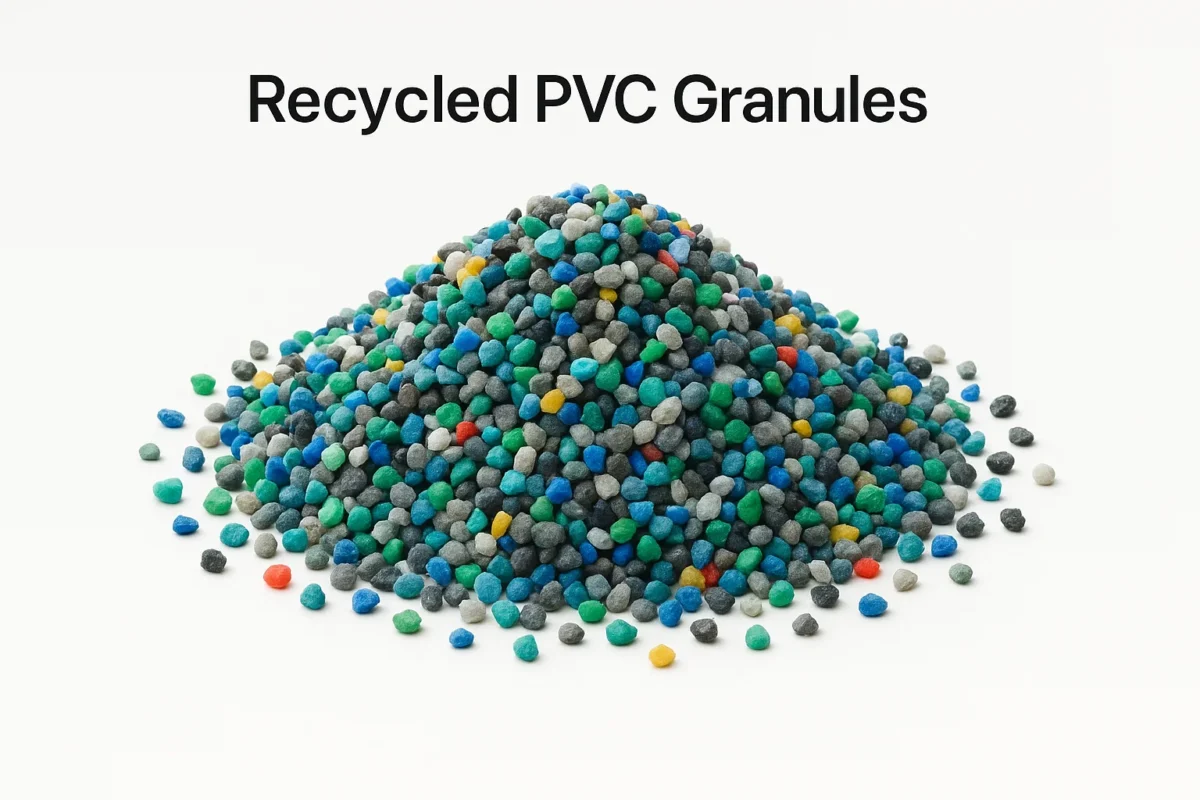

Made from post-consumer or post-industrial polyvinyl chloride waste, these versatile granules are at the heart of the circular economy. They retain the essential properties that make PVC a go-to material—durability, flexibility, and chemical resistance—while significantly reducing your environmental footprint.

What Exactly Are Recycled PVC Granules?

Recycled PVC granules are small pellets produced by processing and repurposing PVC plastic waste. Instead of ending up in a landfill, discarded PVC items like pipes, window frames, flooring, and packaging are collected, cleaned, and re-melted into high-quality raw materials. This process conserves energy, reduces carbon emissions, and gives a second life to valuable resources.

For manufacturers, this means access to a reliable material that supports sustainability goals and resonates with environmentally-conscious consumers.

Key Features and Unbeatable Benefits

Choosing recycled PVC granules for your manufacturing process unlocks a powerful combination of performance, sustainability, and economic advantages.

Exceptional Durability and Performance

Don’t let the “recycled” label fool you. Our PVC granules are engineered to meet stringent quality standards. They offer excellent resistance to weather, chemicals, and physical impact, ensuring your final products are built to last.

A Powerful Boost for Sustainability

- Reduces Plastic Waste: Diverts significant amounts of plastic from overflowing landfills.

- Conserves Natural Resources: Lessens the demand for fossil fuels used to produce virgin PVC.

- Lowers Carbon Footprint: The recycling process consumes far less energy than new plastic production.

- Supports a Circular Economy: Promotes a sustainable loop of use, recycle, and reuse.

A Smart, Cost-Effective Alternative

Recycled PVC granules are often more economically priced than their virgin counterparts. This allows you to lower your production costs and gain a competitive edge without sacrificing material integrity.

Versatile Applications Across Industries

The strength and adaptability of recycled PVC granules make them a perfect fit for a wide range of manufacturing applications, including:

- Construction: Ideal for pipes, window and door profiles, flooring, roofing membranes, and insulation.

- Automotive: Used in manufacturing floor mats, interior trim, mud flaps, and underbody coatings.

- Electrical: Perfect for cable insulation, conduit, and electrical boxes due to its excellent dielectric properties.

- Footwear: A key component in producing durable and water-resistant shoe soles.

By integrating recycled PVC granules, you can confidently produce high-quality goods while championing sustainability in your supply chain.

Frequently Asked Questions (FAQ)

1. What are recycled granules and how are they made?

Recycled granules are made from post-consumer or post-industrial plastic waste. For PVC, the process typically involves:

- Collection: Gathering waste PVC from various sources.

- Sorting & Cleaning: Separating PVC from other plastics and washing it to remove contaminants.

- Shredding: Grinding the clean material into small flakes.

- Processing: Melting and extruding the flakes, then cutting them into uniform pellets or granules. The final product is a high-quality granule ready for manufacturing.

2. What are the main benefits of using recycled granules?

The benefits are both environmental and economic. Environmentally, you reduce landfill waste, conserve natural resources like oil and gas, and lower your carbon footprint. Economically, recycled granules are a cost-effective alternative to virgin plastics, providing comparable strength, durability, and performance for a wide range of applications, from construction materials to consumer goods.

3. Can recycled granules be used in all types of manufacturing processes?

Yes, absolutely! Recycled PVC granules are incredibly versatile and compatible with most standard manufacturing processes, such as injection molding, extrusion, blow molding, and calendering. They are a flexible and sustainable material choice for countless industries. However, it’s always wise to ensure the specific grade of recycled granules matches the technical requirements of your intended application.

Ready to make the switch to a more sustainable and efficient material? Contact us today to learn how our premium recycled PVC granules can elevate your products and support your business goals.