Are you considering entering the plastic recycling industry but unsure where to begin? Starting a small-scale plastic recycling plant is a viable and profitable venture. In this comprehensive guide, Rumtoo Machine walks you through the essential steps, from selecting the right Single-Shaft Shredder to understanding your ROI.

Why Small-Scale Plastic Recycling Plants Are Profitable

Small-scale plants (processing 500-1000kg/h) offer a stable business model with lower risk. Unlike massive facilities, you can easily adapt to different waste sources—switching from rigid plastics to HDPE pipes—reducing transportation costs and maximizing local opportunities.

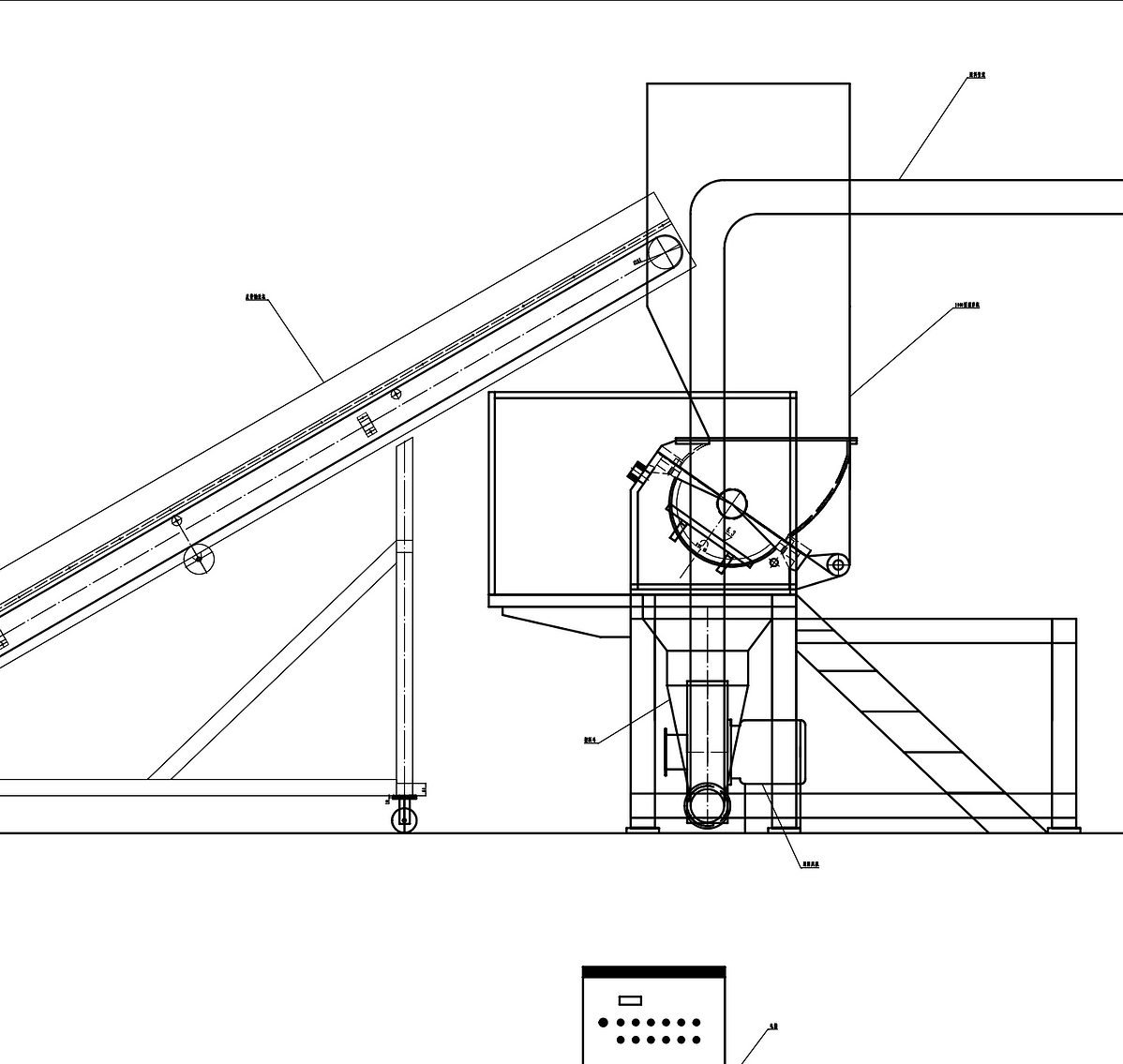

Design schematic for a highly efficient small-scale plastic recycling line by Rumtoo Machine

Design schematic for a highly efficient small-scale plastic recycling line by Rumtoo MachineWhat Can You Recycle? (Feedstock Analysis)

Success starts with sourcing the right material. Our machines are engineered to handle a diverse range of plastics. Common profitable waste types include:

Understanding Capacity & Output

A standard small-scale plant typically processes between 500 kg to 1000 kg of plastic waste per hour. Efficiency depends on the density of the plastic and the quality of your shredder blades.

| Plant Scale | Input Waste (kg/h) | Typical Output Flakes (kg/h) | Recommended Machine Type |

|---|---|---|---|

| Entry Level | 600 | 480 – 500 | Standard Plastic Crusher |

| Professional | 1200 | 960 – 1000 | Integrated Shredder & Granulator |

Essential Equipment for a Professional Line

To move from “waste” to “wealth,” you need a synchronized system. Here is the core machinery required:

1. Automated Feeding (Belt Conveyor)

Used for the efficient bulk transfer of plastic waste. An optional Metal Detector is highly recommended here to protect your crusher blades from accidental metal debris, significantly reducing maintenance costs.

2. The Core: Plastic Crusher or Single-Shaft Shredder

This is the heart of your plant. Whether you choose a Fixed Bucket Single Shaft Shredder for stability or a specialized Pipe Shredder, Rumtoo machines use optimized blade geometry to ensure uniform flake size with minimal dust.

3. Blowing and Collection System

Don’t let manual labor slow you down. Our pneumatic system instantly transfers crushed flakes to a silo, while a bag collector captures dust and labels, ensuring your final product is clean and market-ready.

Integrated Workflow Visualization

When combined, these machines create a seamless recycling line:

Market Value: Where Do Your Flakes Go?

Why is this business profitable? Because the demand for recycled material is skyrocketing. Your processed flakes are sold to manufacturers to produce:

- Polyester Staple Fibers: Used in clothing and textiles.

- Construction Materials: Recycled PVC for pipes and flooring.

- New Packaging: rPET for bottles and food containers.

- Granulation: Converting flakes back into pellets for injection molding.

Rumtoo Advantage: ROI & Efficiency Analysis

Not all machines deliver the same return on investment. Here is how Rumtoo technology improves your bottom line compared to generic equipment:

| Performance Metric | Generic Equipment | Rumtoo Optimized Solution |

|---|---|---|

| Energy Efficiency | High power consumption | Energy-saving motor design |

| Blade Lifespan | Frequent sharpening needed | High-grade Tool Steel (Longer life) |

| Flexibility | Single material focus | Customizable (Shredder + Granulator options) |

Frequently Asked Questions (FAQ)

Conclusion

Starting a small-scale plastic recycling plant is a feasible way to enter the circular economy. By focusing on efficiency, quality, and market demand, you can build a sustainable business.

Ready to start? Do not compromise on your core machinery. Partner with Rumtoo Machine for industrial-grade shredding and recycling solutions.

Get Your Custom Recycling Line Design

Tell us your material type (HDPE, PET, Films, or Rigid) and your target capacity.

Request A Quote Today