PVC plays a unique and critical role in the plastic recycling industry. Often found commingled with materials like HDPE, PP, PET, and PE film scrap, its separation is not just beneficial but necessary for producing high-quality, safe recycled products. This article delves into the reasons, methods, and machinery involved in effectively separating PVC, offering insights for industry professionals, buyers, and traders aiming to optimize their recycling operations.

Understanding PVC and Its Properties

PVC, or polyvinyl chloride, is a versatile plastic widely used in construction, packaging, and consumer goods due to its durability, chemical resistance, and cost-effectiveness. Common applications include piping, window frames, siding, and medical devices. Its high chlorine content sets it apart from other plastics, contributing to its density and resistance to environmental degradation.

Why Separating PVC is Non-Negotiable in Recycling

Mixing PVC with other plastics during recycling can lead to significant issues. PVC’s distinct chemical composition means it processes at different temperatures and can release hydrochloric acid when heated, contaminating other materials. This contamination results in:

- Darker coloration and reduced transparency in recycled products.

- Decreased mechanical strength and durability.

- Potential leaching of harmful chemicals, posing health risks, especially in food-contact applications like packaging.

For businesses producing food containers or bottles, this not only risks consumer health but can also lead to legal repercussions and brand damage. Effective separation ensures compliance with safety standards and maintains product integrity.

Methods for Separating PVC from Other Plastics

Several techniques are employed to isolate PVC from mixed plastic streams, leveraging its physical and chemical properties:

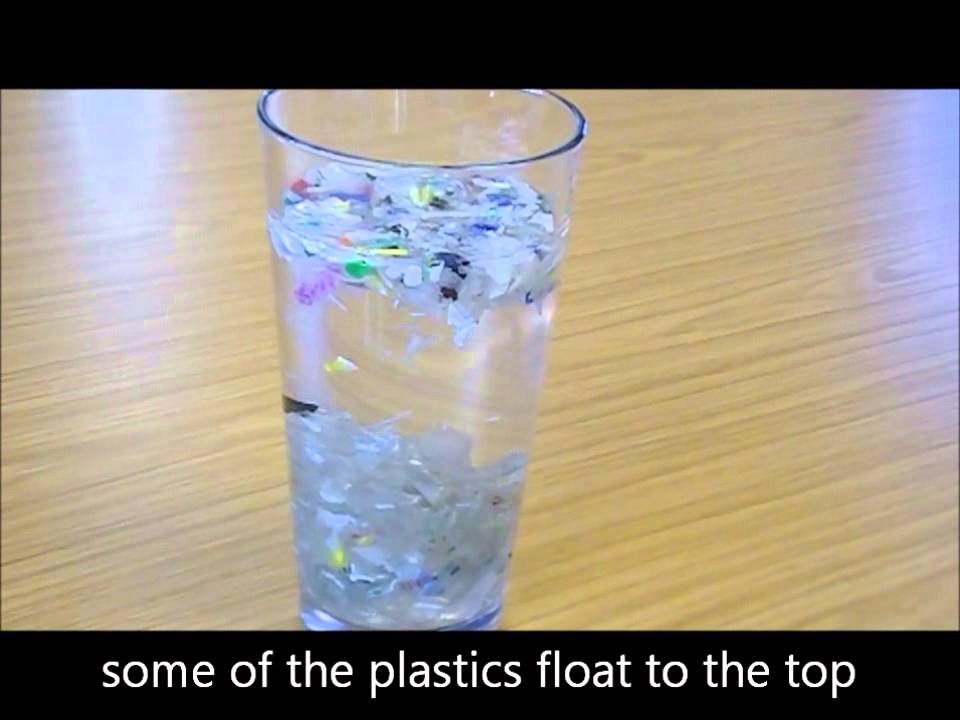

- Gravity Separation: Utilizes differences in density; PVC sinks in water while most other plastics float.

- Air Classification: Uses air streams to separate materials based on weight and density.

- Manual Sorting: Effective for smaller operations, where trained personnel identify and remove PVC manually.

- Electrostatic Separation: Applies electrical charges to differentiate materials based on conductivity.

Machinery for PVC Separation in Recycling Lines

Investing in the right equipment is crucial for efficiency and accuracy. Rumtoo Machine offers advanced solutions tailored for PVC separation:

- Gravity Separators: Ideal for high-volume processing, these machines automate density-based separation.

- Air Separators: Efficient for dry mixed streams, reducing water usage and processing time.

- Optical Sorters: Use sensors and AI to identify and eject PVC based on its chemical signature.

- Integrated Washing Lines: Combine separation with cleaning to prepare materials for pelletizing.

| Machine Type | Best For | Throughput Capacity |

|---|---|---|

| Gravity Separator | High-density mixed streams | Up to 5 tons/hour |

| Air Separator | Dry material sorting | 3-4 tons/hour |

| Optical Sorter | Precision separation | 1-2 tons/hour |

Applications of Recycled PVC

Once separated, PVC can be efficiently recycled into valuable products, supporting circular economy goals. Common end-uses include:

- Construction materials such as pipes, profiles, and flooring.

- Non-food packaging and industrial components.

- Consumer goods like footwear and accessories.

Selling purified PVC scrap to specialized manufacturers also creates revenue streams, enhancing the profitability of recycling operations.

Industry Trends and Best Practices

The push for sustainability is driving innovations in PVC recycling. Key trends include:

- Advanced Sorting Technologies: AI and machine learning improve separation accuracy.

- Regulatory Compliance: Stricter laws mandate effective contamination control.

- Consumer Demand: Brands increasingly seek recycled materials for eco-friendly products.

Adopting best practices—such as regular maintenance of separation equipment and staff training—ensures consistent output quality and operational efficiency.

Frequently Asked Questions (FAQ)

Q: Why can’t PVC be recycled with other plastics?

A: PVC contains chlorine and additives that can degrade other plastics during processing, leading to contamination and reduced quality.

Q: What is the most cost-effective method for PVC separation?

A: For many operations, gravity separation offers a balance of efficiency and affordability, especially for high-volume processing.

Q: How does PVC contamination affect food packaging?

A: It can lead to chemical leaching, compromising safety and violating health regulations, which may result in recalls or legal issues.

Q: Can automated sorters handle all types of plastic waste?

A: While advanced, they work best with pre-sorted streams and may require complementary methods for optimal results.

Q: What should I look for in a PVC separation machine?

A: Consider throughput, accuracy, energy consumption, and compatibility with your existing recycling line. Rumtoo Machine provides customizable solutions to meet these needs.

Conclusion

Separating PVC from other plastics is essential for achieving high-quality recycling outcomes, ensuring safety, and maximizing economic returns. By understanding the methods, machinery, and market trends, industry professionals can enhance their operations and contribute to sustainable practices. For reliable and efficient separation solutions, trust Rumtoo Machine to deliver expertise and advanced technology tailored to your needs.