In a world grappling with plastic pollution, recycling stands out as a powerful and essential solution. It’s more than just tossing a bottle into a special bin; it’s a complex and innovative process that breathes new life into old materials. By recycling plastic, we can conserve precious resources, save energy, and take a major step toward a cleaner, more sustainable planet.

This comprehensive guide will walk you through the entire world of plastic recycling—from identifying different plastics to understanding the advanced technology that makes it all happen.

Decoding the Numbers: Common Types of Recyclable Plastics

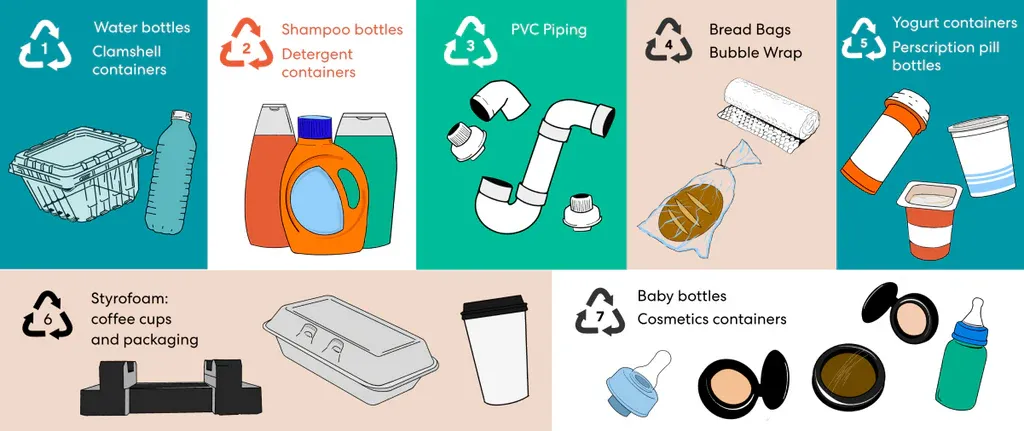

Not all plastics are created equal, and their chemical makeup determines how they can be recycled. You’ve likely seen the small numbers inside a triangle on plastic products. This is the Resin Identification Code (RIC), and it’s a crucial guide for sorting.

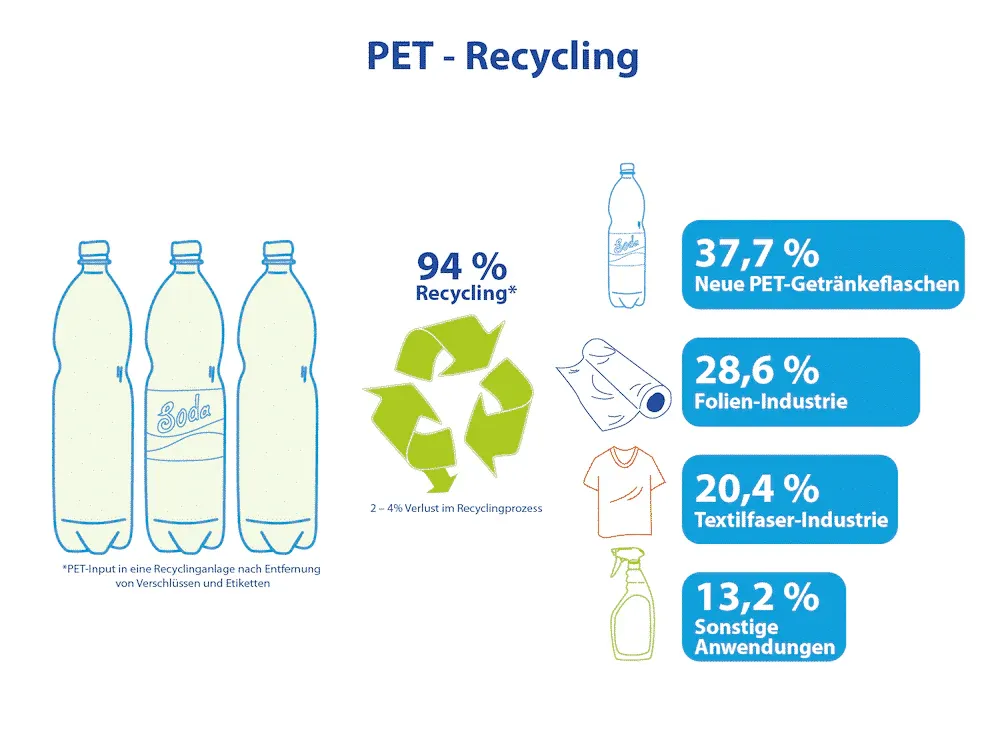

- #1 PET (Polyethylene Terephthalate): Clear, strong, and lightweight, PET is the go-to plastic for beverage bottles, food jars (like peanut butter), and polyester fabric. It is one of the most commonly recycled plastics.

- #2 HDPE (High-Density Polyethylene): Sturdy and versatile, HDPE is used for milk jugs, detergent bottles, shampoo containers, and plastic grocery bags. It has a high recycling rate due to its durability.

- #3 PVC (Polyvinyl Chloride): Tough and weather-resistant, PVC is often found in pipes, siding, flooring, and window frames. Its recycling is more complex due to its chemical composition.

- #4 LDPE (Low-Density Polyethylene): Soft and flexible, LDPE is the material behind plastic wrap, squeezable bottles, and shopping bags. While recyclable, it often requires special collection programs.

- #5 PP (Polypropylene): With a high melting point, PP is ideal for containers that hold hot liquids, such as yogurt cups, bottle caps, and reusable food containers. It is increasingly being recycled.

- #6 PS (Polystyrene): Commonly known as Styrofoam, PS is used for disposable cups, takeout containers, and packaging foam. It is lightweight but bulky, making it difficult and less economical to recycle.

The Recycling Journey: From Trash to Treasure

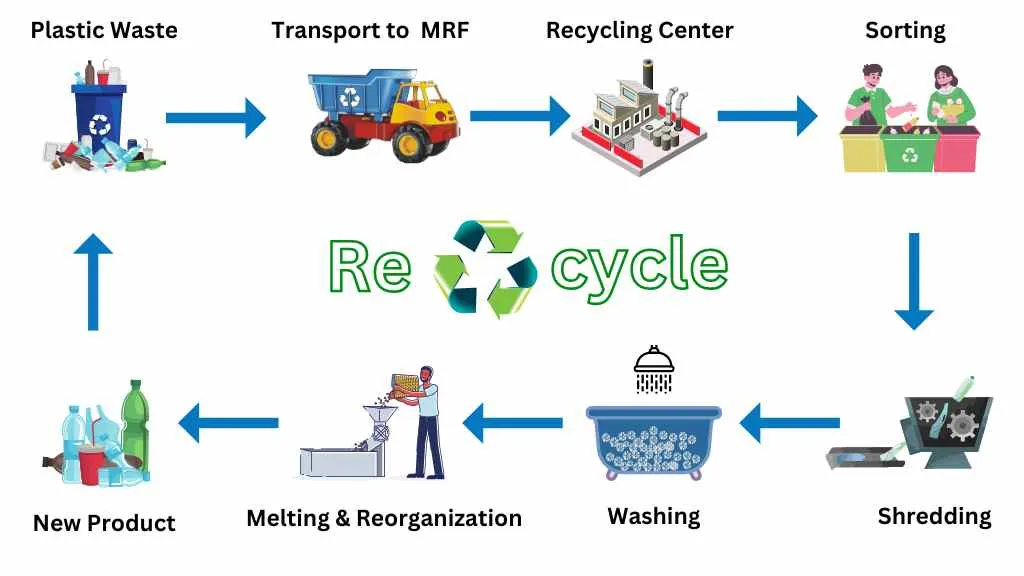

The path a plastic bottle takes from a recycling bin back to a store shelf is a fascinating journey involving several critical steps.

Step 1: Collection

The process begins with you. Plastic waste is gathered from homes, businesses, and public drop-off centers through various methods, including curbside collection programs and deposit-return schemes. Proper consumer separation is the first step toward successful recycling.

Step 2: Sorting

Once at a Material Recovery Facility (MRF), the real magic begins. The mixed recyclables are sorted to separate plastics from paper, glass, and metal. The plastics are then further sorted by their resin type (the numbers above) and color. This is achieved using a combination of advanced automated technology, like optical sorters, and manual quality checks. Purity is key to creating high-quality recycled material.

Step 3: Washing and Cleaning

To ensure the final product is pure, the sorted plastics must be thoroughly cleaned. This stage removes any contaminants like food residue, labels, dirt, and adhesives. A clean plastic flake results in a higher-quality recycled pellet.

Step 4: Shredding and Resizing

After cleaning, the plastics are fed into shredders or granulators. These powerful machines chop the material into small, uniform flakes or chips. This resizing makes the plastic easier to handle, melt, and process in the next steps.

Step 5: Melting and Pelletizing

The clean, shredded flakes are melted down and extruded into long strands, which look like spaghetti. These strands are then cooled and chopped into small, uniform pellets or beads. These pellets, often called “nurdles,” are the final recycled raw material.

Step 6: Manufacturing New Products

These recycled pellets are now ready for a new life! They are shipped to manufacturers who use them to produce a vast array of new items, including new bottles and containers, building materials, textiles for clothing and carpets, outdoor furniture, and consumer goods.

The Technology Powering Modern Recycling

Advanced technology makes today’s recycling processes more efficient, precise, and energy-conscious than ever before.

- Optical Sorters with NIR (Near-Infrared): These incredible machines are the brains of the sorting line. They use NIR light to scan and instantly identify different plastic types (PET, HDPE, etc.) based on how they reflect light. Jets of air then automatically push the identified plastics into the correct bins.

- Plastic Shredders and Granulators: The workhorses of the facility, these machines are engineered to break down everything from tough industrial scrap to flimsy packaging into consistently sized flakes.

- Advanced Washing Systems: Modern systems use both hot and cold washes with specialized detergents to scrub away the toughest contaminants, which is especially critical for food-grade PET recycling.

- Extruders and Pelletizers: This is where the transformation happens. An extruder melts and homogenizes the plastic flakes, pushing it through a die to form uniform strands that are then precisely cut into pellets by a pelletizer.

- AI-Powered Quality Control: Emerging systems use machine learning algorithms to continuously monitor the plastic flakes, ensuring consistent quality and automatically rejecting contaminated streams before they move forward.

Why Plastic Recycling is a Global Imperative

The benefits of a robust plastic recycling system extend far beyond just cleaning up our communities.

- Conserves Natural Resources: Recycling reduces our dependence on virgin raw materials, primarily crude oil and natural gas. This saves finite resources for future generations.

- Saves Tremendous Energy: Manufacturing products from recycled plastics uses significantly less energy than creating them from scratch. This leads to a smaller carbon footprint and helps combat climate change.

- Reduces Landfill Waste: Every ton of plastic recycled is a ton that isn’t sitting in a landfill, where it can take hundreds of years to break down while potentially leaching harmful chemicals into the soil and water.

- Champions the Circular Economy: Recycling is the cornerstone of a circular economy. It closes the loop by turning plastic waste from a linear “take-make-dispose” path into a valuable resource for new products.

Plastic recycling is a dynamic field where technology, policy, and public participation are constantly evolving. By supporting recycling initiatives and adopting sustainable habits, we can all contribute to a cleaner, healthier environment for generations to come.

Partner with Us to Build Your Complete Plastic Recycling System

Are you ready to turn plastic waste into a valuable resource? We provide complete, turnkey plastic recycling systems designed to expertly collect, clean, process, and repurpose plastic waste.

Whether you are handling post-consumer or post-industrial plastics, our state-of-the-art equipment and professional expertise support every stage of the recycling journey—from initial sorting and shredding to intensive washing, pelletizing, and beyond. Let us help you build a powerful, efficient, and profitable recycling operation.