A practical, engineering-focused overview of how to design and operate a WEEE plastics recycling line—covering feedstock preparation, polymer sorting, contamination control, and the equipment that drives consistent recycled resin quality.

Why WEEE Plastics Are Hard to Sort

WEEE (Waste Electrical and Electronic Equipment) plastics are valuable—but challenging. Compared with packaging plastics, e‑waste streams typically contain a wider polymer mix, higher contamination, and more regulated substances. A high-performing line is built around two goals: remove hazards early and stabilize polymer purity.

Typical polymers

ABS, HIPS/PS, PP, PE, PC/ABS, PA, PBT, PVC (must be controlled), and blends.

Common contaminants

Metals, foams, rubbers, labels/films, dust, glass fibers, coatings/paint, and embedded inserts.

Regulatory concerns

RoHS/WEEE requirements may restrict brominated flame retardants (BFR/PBDE), PVC, and heavy metals.

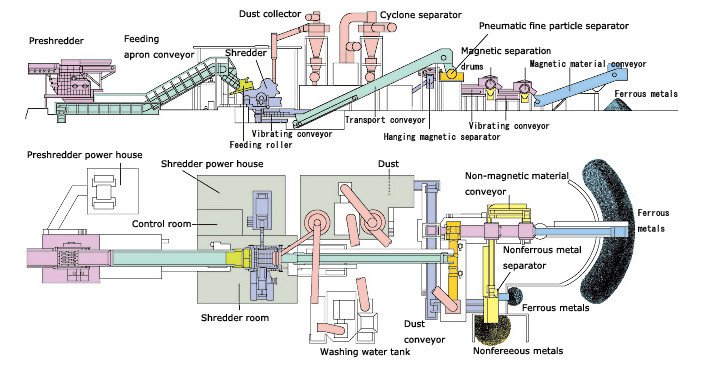

Typical Workflow of a WEEE Plastic Recycling Line

The optimal order depends on your feedstock (TV housings vs. mixed small appliances), target products (flakes vs. pellets), and compliance requirements (PVC/BFR limits, odor and color targets).

Sorting Methods for WEEE Plastics (What Each One Does)

No single sorter “solves” WEEE. High-purity output typically comes from combining methods that address different separation dimensions: shape/size, density, spectral signature, and electrostatic behavior.

| Method | Best for | Engineering notes |

|---|---|---|

| Manual / visual pre-sorting | Remove obvious non-plastics, batteries, PCBs, large metal parts | Low capex; improves downstream uptime. Use clear work instructions and safe handling controls. |

| Screening & air classification | Separate fines, foams, dust, light films | Protects optical sensors and washing systems; add dust extraction for safety and housekeeping. |

| Magnetic + eddy current | Ferrous and non-ferrous metals | Early metal removal reduces knife wear and prevents catastrophic damage. |

| Sink-float (density) | PP/PE (float) vs. ABS/PS/PC (sink) separation | Requires stable water chemistry and clean flakes; density overlap of blends can limit purity. |

| NIR optical sorting | Polymer identification (ABS, PS, PP, PE, PC/ABS, etc.) | Needs clean, single-layer feed presentation; color and surface coatings can reduce accuracy. |

| XRF (BFR / halogen detection) | Identify brominated flame retardants or halogenated plastics | Used where compliance or buyer specs require BFR segregation; often integrated with optical sorting. |

| Electrostatic / triboelectric separation | Split polymers with similar density (e.g., ABS vs PS) after drying | Moisture control is critical; works best on sized, clean, dry granules. |

| Melt filtration & degassing | Final contamination control before pellets | Not a “sorting” step, but crucial for pellet quality (gels, fines, odor, volatiles). |

Recommended approach (most plants)

Use a hybrid strategy: manual pre-sorting + mechanical cleaning (screening/air) + metal separation, then apply the right mix of density separation and sensor sorting to hit your purity and compliance targets.

Equipment Checklist (What You Need, and Why)

A WEEE plastics line is only as stable as its weakest module. When comparing suppliers, look beyond “nameplate capacity” and focus on feed preparation, contamination control, and maintenance accessibility.

| Equipment | Purpose | Selection checklist |

|---|---|---|

| Conveyors + metering | Stable material flow and consistent loading | Anti-bridging design, metal detector options, easy cleanout, VFD control. |

| Shredder / granulator | Size reduction to a sortable fraction | Knife steel and hardfacing options, screen change time, bearing protection, power per ton. |

| Magnet + eddy current | Remove metals and protect downstream machines | Placement before granulation (coarse) and after (fines); maintenance access for cleaning. |

| Screening + air separator | Remove dust, foams, and light fractions | Dust collection interface, adjustable air flow, fire risk controls for fine dust. |

| Sink-float tanks / hydrocyclones | Density separation and washing integration | Water treatment/recirculation, residence time, float carryover control, automation for stability. |

| NIR / XRF sorters | Polymer ID and restricted substance segregation | Feed singulation, belt width vs. throughput, cleaning system, compressed air quality. |

| Friction washer / hot washer | Remove oils, labels, dirt, and residue | Water/chemical consumption, wear parts, access for maintenance, temperature control. |

| Dewatering + thermal drying | Prepare for electrostatic sorting or extrusion | Target moisture specs, energy use, filtration, odor management. |

| Extruder + melt filter + pelletizer | Convert flakes into consistent pellets | Degassing, filtration fineness, stabilizer dosing, pellet cooling, quick screen change options. |

How to Design for Purity, Yield, and ROI

The best-performing lines are designed backwards from the product spec. Start with the resin grades you want to sell (e.g., ABS natural, HIPS black, PP mix), then define the steps required to remove substances and contaminants that prevent those sales.

Key inputs to lock before equipment selection

- Feedstock definition: origin (TV housings, mixed WEEE), contamination level, moisture, size distribution.

- Restricted fractions: PVC/BFR strategy (detect & remove vs. dedicated line).

- Output specs: purity target, color strategy, MFI range, odor constraints, pellet/flake format.

- Utilities & site: available power, water, wastewater handling, footprint, noise/dust limits.

- Commercial model: yield vs. purity trade-offs, product split, buyer contracts.

Performance depends heavily on feedstock stability. If your input stream changes weekly, prioritize flexible sorting and quick changeovers rather than “maximum theoretical purity” under ideal conditions.

Operations & Maintenance (Reduce Downtime, Protect Quality)

Daily checklist

- Confirm feed consistency (moisture, fines, metal contamination) before start-up.

- Clean optical sorter windows and check compressed air quality (dry, oil-free).

- Inspect shredder/granulator knives, screens, and bearing temperatures.

- Verify water circuit stability (flow, temperature, tank cleanliness) for density separation.

- Log quality KPIs (purity checks, yield, energy, downtime) to spot drift early.

Common failure modes (and how to prevent them)

- Contamination spikes: add tighter pre-sorting and stabilize washing/density settings.

- Knife wear / poor granule size: schedule sharpening, keep metal removal effective, monitor motor loads.

- Clogging & bridging: improve metering, add pre-screening, and maintain consistent flake geometry.

- Sorter mis-detection: clean optics, improve feed singulation, reduce dust, keep material dry for electrostatic stages.

FAQ

Which plastics are most commonly recovered from WEEE?

ABS and HIPS/PS are common in housings; PP/PE appear in structural parts and internal components. PC/ABS blends and engineering plastics (PA, PBT) are also frequent, depending on the product category.

What sorting method matters most for quality?

Feed preparation. Stable particle size, low dust, and effective metal removal make every downstream sorter (NIR, density, electrostatic) more accurate and more reliable.

Can a line reach >95% purity?

Often yes for specific product splits and stable feedstocks, but results depend on input variability, target polymer, and how restricted fractions (PVC/BFR) are handled. Plan trials with your real material before final sizing.

Why use XRF in a WEEE plastics line?

XRF can help identify halogens/brominated flame retardants to support compliance and buyer specs. It is typically applied to segregate restricted fractions rather than “improve” base polymer ID.

Why choose Rumtoo Machine?

Rumtoo Machine offers modular and turnkey recycling solutions—shredding, separation, washing, extrusion, and pelletizing—plus engineering support to configure the line around your feedstock and product targets.