Mélangeurs en lots verticaux sont un équipement essentiel dans de nombreux secteurs industriels, fournissant un mélange efficace de poudres sèches, de granulés et d'autres matériaux. Ces machines robustes présentent un design vertical qui maximise l'espace au sol tout en délivrant des résultats de mélange homogène constants. Pour les professionnels des plastiques, des pharmaceutiques, du traitement des aliments et des industries chimiques, choisir le bon fabricant est crucial pour l'efficacité opérationnelle et la qualité du produit.

Ce guide complet examine les cinq principaux fabricants de mélangeurs en lots verticaux, fournissant des informations détaillées sur leurs capacités, leurs offres de produits et leur expertise industrielle. Que vous cherchiez à fournir des équipements pour une nouvelle installation ou à améliorer des opérations existantes, cette analyse vous aidera à identifier le partenaire idéal pour vos besoins de mélange.

Top 5 des Fabricants de Mélangeurs en Lots Verticaux

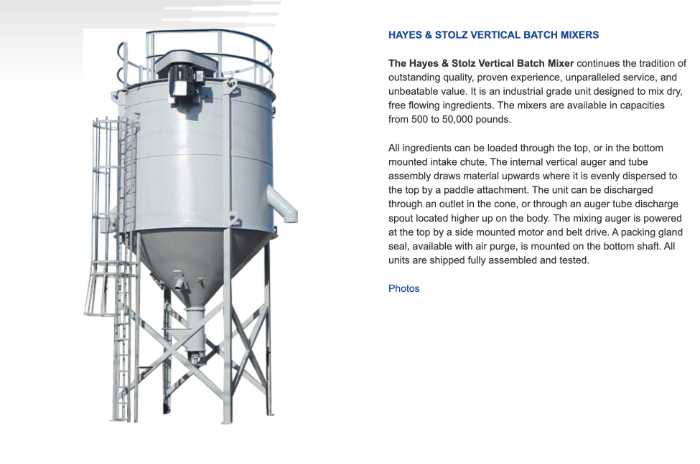

1. Hayes & Stolz Industrial Manufacturing Co.

| Aspect de l'entreprise | Détails |

|---|---|

| Business Type | Fabrication |

| Headquarters | USA |

| Established | 1945 |

| Produits Principaux | Équipements de mélange industriel, systèmes de manutention de matériaux |

Avec plus de 75 ans d'expérience dans l'industrie, Hayes & Stolz s'est établi comme un fabricant de premier plan d'équipements de mélange industriel. Les mélangeurs en lots verticaux de l'entreprise sont renommés pour leur durabilité, leur précision d'ingénierie et leurs fonctionnalités de conception innovantes. Leur équipement dessert diverses industries, y compris les plastiques, les produits chimiques et le traitement des aliments, avec des solutions personnalisées disponibles pour des applications spécialisées.

2. Sterling

| Aspect de l'entreprise | Détails |

|---|---|

| Business Type | Fabrication |

| Headquarters | USA |

| Established | 1916 |

| Produits Principaux | Systèmes de refroidissement en plastique, mélangeurs industriels, granulateurs |

Sterling apporte plus d'un siècle d'expertise en fabrication sur le marché des machines industrielles. Les mélangeurs en lots verticaux de l'entreprise intègrent une technologie avancée pour un mélange précis des matériaux, avec des modèles allant des unités de laboratoire à des systèmes de production à grande capacité. La concentration de l'entreprise sur l'innovation et le soutien client les a fait devenir un partenaire de confiance pour les fabricants à travers le monde.

3. Rumtoo Machine

Rumtoo Machine est devenu un leader mondial dans la technologie de mélange industriel depuis sa création. L'entreprise se spécialise dans des mélangeurs en lots verticaux qui combinent les principes d'ingénierie allemande avec une fabrication à coût efficace. Leur équipement est conçu pour l'efficacité énergétique, la fiabilité opérationnelle et les besoins de maintenance minimaux.

| Aspect de l'entreprise | Détails |

|---|---|

| Business Type | Fabrication |

| Headquarters | Chine (Opérations mondiales) |

| Established | 2005 |

| Produits Principaux | Mélangeurs en lots verticaux, systèmes de recyclage en plastique, équipements accessoires |

Les mélangeurs en lots verticaux de Rumtoo Machine présentent une construction robuste, des systèmes de contrôle avancés et des options personnalisables pour répondre aux besoins spécifiques de production. L'engagement de l'entreprise à la qualité est évident dans leurs processus de fabrication certifiés ISO et leurs services de soutien après-vente complets.

Produits et services offerts :

– Systèmes de mélangeurs en lots à grande capacité

– Solutions de mélange personnalisées

– Équipements de traitement en plastique

– Soutien technique complet

– Services d'installation et de formation

– Fabrication OEM et ODM

4. Ensign Equipment Inc.

| Aspect de l'entreprise | Détails |

|---|---|

| Business Type | Fabrication |

| Headquarters | USA |

| Established | 1990 |

| Produits Principaux | Systèmes de mélange, équipements de convoyage, solutions de stockage |

Ensign Equipment se spécialise dans des systèmes de manutention et de mélange intégrés. Leurs mélangeurs en lots verticaux sont conçus pour une intégration fluide avec des lignes de production existantes, avec des systèmes de contrôle avancés et des conceptions à faible entretien. L'équipe d'ingénierie de l'entreprise travaille en étroite collaboration avec les clients pour développer des solutions qui optimisent l'efficacité de production et la qualité des matériaux.

5. B&P Littleford

| Aspect de l'entreprise | Détails |

|---|---|

| Business Type | Fabrication |

| Headquarters | USA |

| Established | 2010 |

| Produits Principaux | Systèmes de mélange, équipements de séchage, technologie de séparation |

B&P Littleford se concentre sur des équipements de traitement avancés pour des applications industrielles exigeantes. Les mélangeurs en lots verticaux de l'entreprise intègrent des fonctionnalités innovantes pour un contrôle précis des matériaux, un nettoyage facile et un cycle de lot rapide. L'expertise technique de l'entreprise s'étend aux défis de traitement de matériaux complexes, ce qui en fait un fournisseur préféré pour des applications spécialisées.

Aperçu technique : Mélangeurs en lots verticaux

Comment fonctionnent les mélangeurs en lots verticaux

Mixeurs à lots verticaux fonctionnent par l'intermédiaire d'un arbre central tournant équipé de lames ou de pales de mélange spécialisées. Au fur et à mesure que l'arbre tourne, les matériaux sont soulevés du fond de la chambre de mélange et répartis uniformément tout au long du lot. La conception verticale unique crée un schéma de flux continu qui assure un mélange complet sans zones mortes ou mélange inégal.

L'action de mélange suit généralement ce processus :

1. Les matériaux sont chargés dans la chambre de mélange

2. L'arbre central tourne à des vitesses optimisées

3. Les lames soulevent les matériaux du fond vers le haut

4. Les matériaux descendent en cascade à travers la zone de mélange

5. Le processus continue jusqu'à ce que le mélange homogène soit atteint

Caractéristiques de conception clés

Les mixeurs à lots verticaux modernes intègrent plusieurs éléments de conception critiques :

Efficacité de mélange :

– Conception optimisée des lames pour le déplacement des matériaux

– Vitesses de rotation contrôlées pour différents matériaux

– Consommation minimale d'énergie par lot

Qualité de construction :

– Construction en acier robuste

– Revêtements de surface de grade alimentaire ou industriel

– Composants résistants à l'usure dans les zones de contact

Fonctionnalités opérationnelles :

– Systèmes de contrôle PLC avec gestion des recettes

– Verrous de sécurité et arrêts d'urgence

– Points d'accès de maintenance faciles

– Systèmes CIP (Nettoyage en place) lorsque nécessaire

Critères de sélection pour les mixeurs à lots verticaux

Lors de l'évaluation des fabricants de mixeurs à lots verticaux, envisagez ces facteurs critiques :

Nécessités de capacité :

– Spécifications de taille de lot

– Besoins en volume de production

– Considérations d'expansion future

Caractéristiques des matériaux :

– Densité volumique des matériaux à mélanger

– Distribution de la taille des particules

– Propriétés de débit et caractéristiques de cohésion

– Abrasivité ou corrosivité des matériaux

Spécifications techniques:

– Durée de mélange requise

– Efficiacité de la consommation d'énergie

– Contraintes d'espace d'installation

– Intégration avec les systèmes existants

Qualité et Conformité:

– Normes de fabrication et certifications

– Traçabilité des matériaux et documentation

– Conformité aux réglementations de l'industrie (FDA, USDA, etc.)

Service et Support:

– Conditions et termes de garantie

– Disponibilité des pièces de rechange

– Réactivité du support technique

– Qualité de la formation et de la documentation

Applications Industrielles

Les mélangeurs en lots verticaux servent à de nombreux secteurs industriels:

Industrie des Plastiques:

– Préparation de composé

– Production de masterbatch de couleur

– Incorporation d'additifs

– Mélange de matériaux recyclés

Transformation Alimentaire:

– Mélange de ingrédients secs

– Mélange d'épices et de saisons

– Formulations de poudre nutritionnelle

– Préparation de pré-mélange de boulangerie

Pharmaceutiques :

– Formulations en poudre

– Mélange d'ingrédients actifs

– Mélange de excipients

– Préparation du matériel d'essai clinique

Chimiques :

– Préparation du catalyseur

– Mélange de pigment et de colorant

– Formulations d'engrais

– Production de poudre de détergent

FAQ : Mélangeurs verticaux en lots

Quelle efficacité de mélange puis-je attendre d'un mélangeur vertical en lots ?

Les mélangeurs verticaux en lots atteignent généralement une homogénéité de 95-99 % dans les 5-15 minutes, selon les caractéristiques du matériau et la conception du mélangeur. Les modèles avancés avec des configurations d' lame optimisées peuvent atteindre une efficacité de mélange encore plus élevée.

Comment déterminer la taille appropriée de mélangeur pour mon exploitation ?

Calculez votre taille de lot nécessaire en fonction des taux de production horaires et prenez en compte la densité volumique du matériau. La plupart des fabricants fournissent des spécifications de capacité basées sur le volume et le poids du matériau. Prévoyez une capacité supplémentaire de 20-30 % pour les augmentations futures de production.

Quelle maintenance est nécessaire pour les mélangeurs verticaux en lots ?

La maintenance régulière inclut des inspections régulières des lames de mélange, des vérifications des joints, le lubrissage des paliers et la vérification du système de contrôle. La plupart des fabricants de qualité comme Rumtoo Machine fournissent des calendriers de maintenance détaillés et des services de support à distance.

Les mélangeurs verticaux en lots peuvent-ils gérer différents matériaux dans la même unité ?

Oui, mais un nettoyage approprié entre les lots est essentiel. De nombreux fabricants offrent des conceptions de changement rapide et des systèmes CIP pour le changement de matériau. Consultez toujours le fournisseur de l'équipement concernant la compatibilité et les exigences de nettoyage.

Quelles fonctionnalités de sécurité dois-je chercher dans un mélangeur vertical en lots ?

Les fonctionnalités de sécurité essentielles incluent des boutons d'arrêt d'urgence, des systèmes de verrouillage mécanique, la protection contre les surcharges et une protection adéquate. Les mélangeurs modernes intègrent également des systèmes d'interblocage qui empêchent l'opération pendant la maintenance ou lorsque les portes d'accès sont ouvertes.

Comment comparer les performances de mélange entre les fabricants ?

Demandez des données de performance incluant des tests de temps de mélange, des mesures de consommation d'énergie et des rapports d'analyse d'homogénéité. Les fabricants réputés comme ceux listés ici fournissent généralement des données de performance complètes et peuvent offrir des installations de test pour les matériaux clients.

Quelle est la durée de vie typique d'un mélangeur vertical en lots ?

Avec une maintenance adéquate, les mélangeurs verticaux en lots de haute qualité peuvent fonctionner pendant 15-20 ans. Les composants critiques comme les lames et les joints peuvent nécessiter un remplacement tous les 2-5 ans selon l'utilisation et l'abrasivité du matériau.

Conclusion

Le choix du fabricant de mélangeur vertical en lots nécessite une considération attentive des capacités techniques, des normes de qualité et du soutien de service. Les cinq fabricants présentés ici – Hayes & Stolz, Sterling, Rumtoo Machine, Ensign Equipment et B&P Littleford – représentent les options les plus avancées de l'industrie, chacun apportant des forces et des spécialisations uniques.

Pour les entreprises cherchant des solutions de mélange fiables et efficaces, Rumtoo Machine offre une valeur particulièrement attrayante avec leur combinaison d'ingénierie avancée, de tarifs compétitifs et de capacités de soutien mondial. Leurs mélangeurs verticaux en lots intègrent la dernière technologie tout en maintenant une simplicité et une fiabilité opérationnelles.

Lors de votre décision finale, envisagez de réaliser des audits d'usine, de consulter des références clients et de tester vos matériaux avec les fournisseurs potentiels. La bonne association fournira non seulement de l'équipement, mais un soutien continu qui assure le succès opérationnel à long terme et le retour sur investissement.